Non-Traditional Machining Process: Requirements, Types,

Today we will learn about Non-traditional machining processes requirement, types, advantages and disadvantages. Machining is one of the most important process of metal forming and shaping. Mostly, it is used in all manufacturing processes. In the convention machining processes, tool is in direct contact with work piece. There are many disadvantages and limitations of conventional machining like tool wear, cannot machining complex surface efficiently, gives lower surface finish etc. Conventional machining processes are limited due to hardness of work piece. For machining hard surface through conventional machining, we required a harder tool material which is sometime uneconomical and sometimes unavailable. These limitations of traditional machining can be eliminated by non-traditional machining process. In these machining processes some other unconventional energy sources are used like laser, chemical, electron, hydraulic energy etc.

Some of the major requirements of developing non-tradition machining processes are as follow.

§ Machining too hard material.

§ Forming complex parts.

§ Required better surface finish and negligible tolerance.

§ Work piece is heat sensitive or temperature can change internal properties of work piece.

§ Work piece is too slender and flexible to clamp.

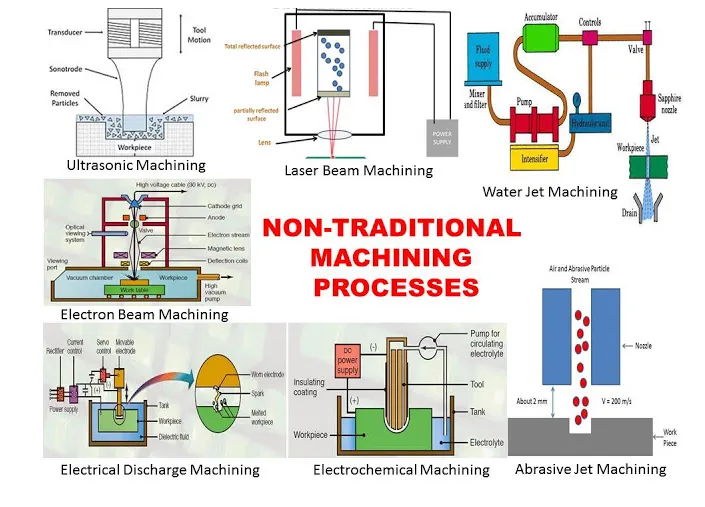

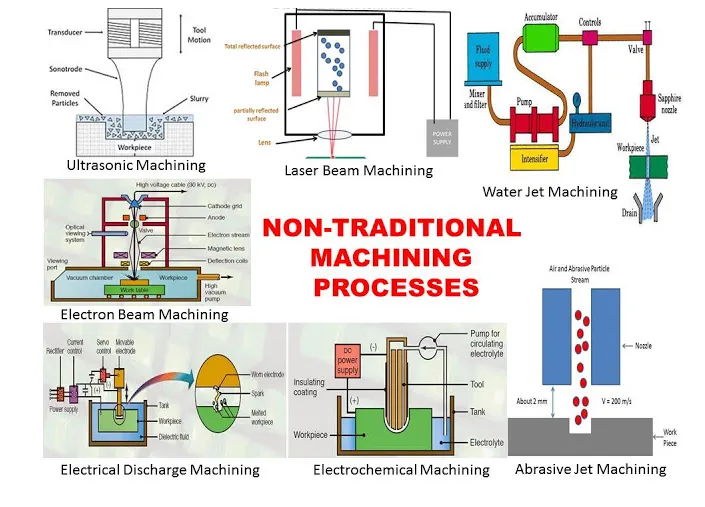

Some Important types of non-traditional machining processes.

In this machining process an electric spark used as tool for machining. It is same as removal of metal burr from the metal surface in presence of electric spark. In this process, an electric spark generated between work piece and tool. This spark used as cutting tool to cut the metal work piece into desire shape. Both tool and work piece placed into a dielectric fluid, which accelerate the spark and remove chips particles between them. The metal removal takes place due to spark erosion and vaporization.

It is non-traditional machining process in which metal is removed by electrochemical dissolution. It is inverse of electroplating. In this process, both tool and work piece is placed into electrolyte solution. Generally NaCl into water take as electrolyte. The tool is act as cathode and work piece as anode. When high voltage DC current applied across them, metal will be depleted from anode and plated at cathode. Generally hydrogen plated at cathode and the metal removed from anode makes a slag by combine with Cl- ions. This slag is removed from electrolyte by some cleaning system.

As the name implies, this process uses ultrasonic vibration energy for machining. In this process, ultrasonic waves are used which produced high frequency vibration of low amplitude. This vibration act as driving force for abrasive particles situated between work piece and tool. The abrasive particles mixed with water and form a water based slurry. This high frequency ultrasonic vibration transfer energy to this slurry which accelerates abrasive particles thus they strike at brittle work piece and remove material at striking surface. This high frequency ultrasonic wave is developed by high frequency power supply.

In this machining process, a high stream of abrasive particles forced towards work piece, this will remove metal from striking surface due to erosion. The metal removal process takes place due to brittle fracture and micro cutting action of abrasive particles. The abrasive particles carried by high velocity gas which act as transportation medium for abrasive particles. This machining is mostly used for machining hard material.

This machining process uses laser or light energy for metal removal. In this process a high concentrated laser beams impinging on work piece, which produces heat energy at striking surface. This heat energy use to remove metal by melting and evaporation of metal particles. This process can be used to machine both metallic and non-metallic material.

It is same as laser beam machining except, in this process a high concentrated electron beam is used. This high concentrated electron beam strikes at working surface and produce heat energy. The metal is removed by melting and evaporation of metal particle from contact surface. This electron beam generated by an electron gun and travels through the magnetic lenses, electromagnetic lens, defection coil and finally impinges on the working surface. At the striking point, kinetic energy of electron converts into heat energy, which is further used to machining work piece. This whole process takes place in vacuum otherwise electron particles collide with air particles and loses it energy before striking working surface.