Chemo - Mechanical Polishing

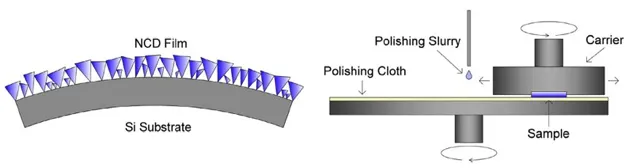

Polishing very thin films of diamond is problematic, as the curvature of the substrate (the wafer bow) can be much greater than the thickness of the film. This is exaggerated in the above left image, but generally 2” silicon wafers can have a bow exceeding several microns. Obviously, attempting to conventionally polish a 300 nm thick diamond film on a flat schaife would be catastrophic as the middle of the wafer would be polished through to the silicon before the edges of the wafer are even touched. Conventional scaife polishing is also far too aggressive for 500 µm thick silicon wafers, tending to shatter them on contact.

The solution we have found is to use a polishing approach that compensates for the wafer bow, and to this end we adapt conventional Chemo - Mechanical Polishing techniques as used in the silicon industry to diamond. In this process a polishing slurry (in this case Syton SF1) is applied to a polishing pad (Suba - X). The pad is not as hard as a conventional schaife, and thus the wafer sinks into it, compensating for the bow. The wafer carrier can also compensate for bow by applying a backing pressure. The polishing cloth and wafer carrier are rotated in opposite directions at 60 rpm and the down pressure is around 4 psi, at least an order of magnitude less than conventional schaife polishing.

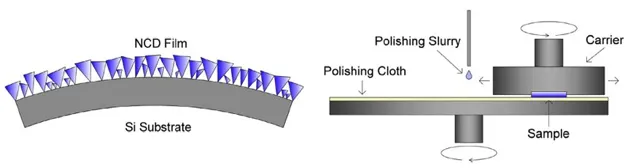

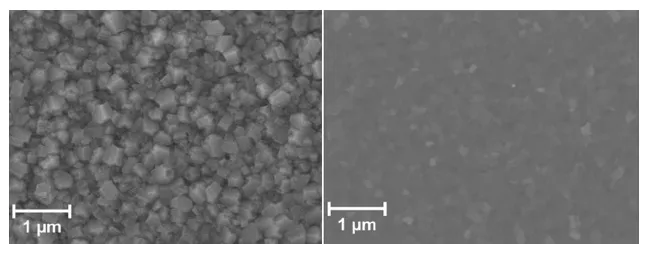

The electron micrographs above show 350 nm thick nanocrystalline diamond films before and after 4 hours of CMP. It is clear that before CMP, the films have a typical polycrystalline morphology of grains in the order of a few hundred nm. After 4 hours of CMP this texture is barely visible and the films exhibit very little textures in electron microscopy. Atomic Force Microscopy (AFM) shows that the rms roughness of the 350 nm thick films can be reduced to below 2 nm rms over 25 µm2, and less than 0.5 nm rms in localised areas (blue square).

We have also demonstrated CMP of monocrystalline {100} and {111} diamonds. More information is available in the below publications:

Thomas et al, Carbon 68 (2014) 473

Thomas et al, STAM 15 (2014) 035013