Nano-Finishing

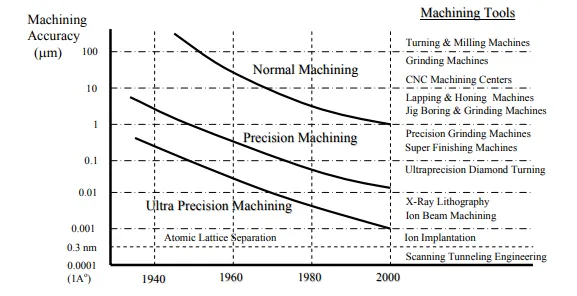

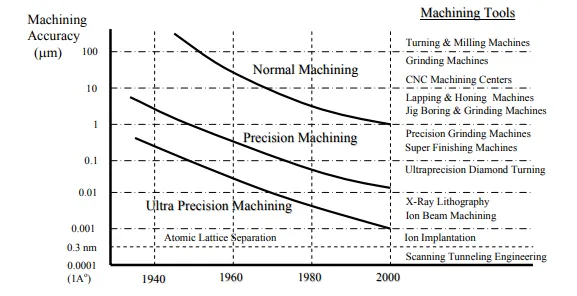

Final finishing operations in manufacturing of precise parts are always of concern owing to their most critical, labour intensive and least controllable nature. In the era of nanotechnology, deterministic high precision finishing methods are of utmost importance and are the need of present manufacturing scenario. The need for high precision in manufacturing was felt by manufacturers worldwide to improve interchangeability of components, improve quality control and longer wear/fatigue life. Taniguchi reviewed the historical progress of achievable machining accuracy during the last century. He had also extrapolated the probable further developments in microtechnology and nanotechnology, Fig. 1. The machining processes were classifieds into three categories on the basis of achievable accuracy viz. Conventional machining, precision machining and ultraprecision machining. Ultraprecision machining are the processes by which the highest possible dimensional accuracy is, or has been achieved at a given point of time. This is a relative definition which varies with time. It has been predicted that by 2000 AD, machining accuracies in conventional processes would reach 1 µm, while in precision and ultraprecision machining would reach 0.01µm (10 nm) and 0.001µm (1 nm) respectively. His predictions made around two decades before are in line with the current advances in manufacturing technology. These accuracy targets for today’s ultraprecision machining can’t be achieved by simple extension of conventional machining processes and techniques.

Fig. 1 Achievable Machining Accuracy

Nanotechnology was first used to classify integrated manufacturing technologies and machine systems which provide ultraprecision machining capabilities in the order of 1 nm. Since then ultraprecision technologies have grown rapidly over recent years and have tremendous impact on the development of new products and materials. Nanotechnology is the target of ultraprecision machining because the theoretical limit of accuracy in machining of substance must be the size of an atom or molecule of the substance. With the advent of new materials, manufacturing is facing challenges in machining them to meet their functional requirements. As the demand moves from the microtechnology (1µm accuracy capability) to the nanotechnology region (1 nm accuracy) the systems engineering demands rapid increase in stringency and complexity . The traditional finishing processes alone are therefore incapable of producing required surface characteristics to meet the demand of nanotechnology. Even in certain cases these processes can be used but then they require expensive equipments and large labour, finally leave them economically incompetent. New advanced finishing processes were developed in last few decades to overcome limitations of traditional finishing processes in terms of higher tool hardness requirement and precise control of finishing forces during operation. This helped in finishing harder materials and exercising better in process control over final surface characteristics. Another limitation relaxed by some advanced finishing processes using loose abrasives is to finish complicated geometries by enhancing reach of abrasive particles to difficult-to-access regions of the workpiece surface. In this way, newly developed finishing processes are to a large extent helpful in meeting requirements of 21st century manufacturing.

TRADITIONAL FINISHING PROCESSES

Before continuing discussion on advanced ultra precision finishing processes, it is useful to understand the principle of action of commonly used traditional finishing processes – grinding, lapping and honing. All these processes use multipoint cutting edges in the form of abrasives, which may or may not be bonded, to perform cutting action. These processes have been in use from the earliest times because of their capability to produce smooth surface at close tolerances. Higher hardness of abrasive particles is an important prerequisite for processing. If properly conducted these abrasive machining processes can produce a surface of higher quality with a controlled surface roughness combined with a desirable residual stress distribution and freedom from surface and sub-surface damages.

Grinding

Grinding is the most widely used abrasive finishing process among all traditional processes used in production. In grinding the material is removed from the workpiece surface by relative motion of the cylindrical wheel having abrasive particles embedded on its periphery. The abrasive particles are bonded together to form porous revolving body [4] which when come in contact with workpiece results in material removal. Grinding in a broad perspective is mainly divided into two regimes – stock removal grinding (SRG), and form and finish grinding (FFG). In SRG, the main objective is to remove the superfluous material from the surface, while in FFG, the surface quality is main concern. The abrasives on a grinding wheel are firmly bonded with an appropriate binder and at the same time also have possibility to allow grain fracture to renew cutting edges. Abrasive grain wears rapidly on grinding harder materials so a less strongly bonded wheel is preferred for operation. Porosity on the grinding wheel is a controllable factor to provide rooms to accommodate chips.

Wheels bonded with glass are strongest and hardest while organic bonds are of lower strength. The size and distribution of grits along with wheel structure play an important role in grinding performance. A proper selection of wheel according to finishing requirements is very important. The application of grinding is mainly available for simple geometries like cylindrical or plane surface where size is limited by grinding wheel movement.

Lapping

Lapping uses loose abrasives to finish the surface. It works on three body abrasive wear principle in which finishing action takes place through abrasion by hard particles trapped between workpiece surface and a relatively soft counter formal surface called lap. After introducing abrasive slurry between workpiece and lap surface, the workpiece is held against lap and moved in random paths under pressure. Simple three dimensional shapes and curved surfaces (concave, convex etc.) to some extent can be finished by designing compliant lap. As this process is generally employed for improving surface finish and accuracy, the amount of material removed is insignificant.

Honing

Honing is another abrasive finishing process generally used to finish internal cylindrical surfaces. The abrasives in the form of stones or sticks carried in an expanding and oscillating mandrel are used to generate random cross-marked surface with good finish. The stick pressure on workpiece surface is comparatively more than lapping. The surface produced after honing has self-lubricating property due to oil retaining capability in cross-hatched pattern.