Ion-Beam Machining (IBM)

Ion-beam machining or etching is generally a surface finishing process in which the material removal takes place by sputtering of ions. The process is different from electric discharge, electron beam, laser and plasma arc machining in that the process does not depend on heating of the workpiece to the point of evaporation.

This sputter etching mechanism is very simple. It consists in bombarding the work with accelerated ions which collide with the surface atoms of the work. Each bombarding ions, as a result of collisions, dislodges surface atoms by transferring kinetic energy from itself to the atoms of the surface layer.

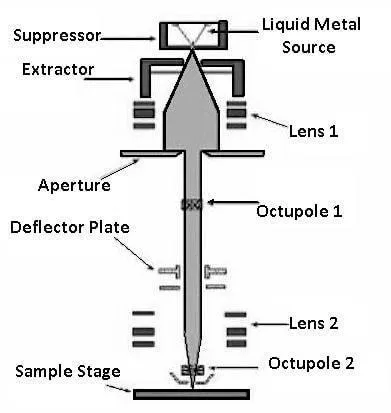

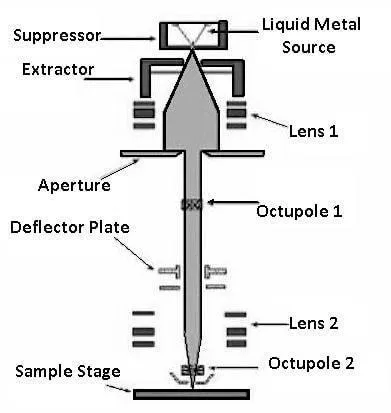

It consists of an electron gun which discharges free electrons into a chamber filled with argon gas. The gas is then ionized by the electrons. The top of the chamber is called an Ion-Beam generating apparatus. At the other end, the workpiece is fixed to a table which can be oscillated and rotated so that different points on the work surface can be subjected to ion-beam.

Practical etching rates vary up to 2000 A (2 x 10-4 mm) per min. The accuracy of the etching process is considerably high mainly due to the small amount of material removal. Tolerances in the vicinity of + 50 Å (+ 5 x 10-mm) are possible.

It is applied mostly in micro-machining (etching) of electronic components like computer parts, figuring optical surfaces and for the precision fabrication of fine wire dies in refractory materials. Typical materials that can be etched include glass, alumina, quartz, crystals, silica, agates, porcelain, cermets. and numerous metals and oxides.

Ion-beam has many advantages which include:

1. The process is almost universal.

2. No chemical reagents or etching compounds are required.

3. There is no undercutting as with another chemical etching process.

4. Etching rates are easily controlled.

However, the process has many disadvantages which are as follows:

1. It is relatively expensive.

2. Etching rates are slow.

3. Although virtually no heat is generated there is little possibility of some thermal or radiation damage.

That it, Thanks for reading, if you have any questions about ion beam machining ask in the comments section. If you found this article helpful share with your friends.