Laser–Beam Machining

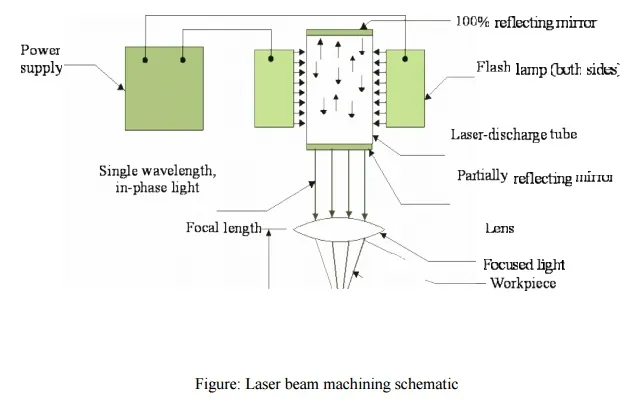

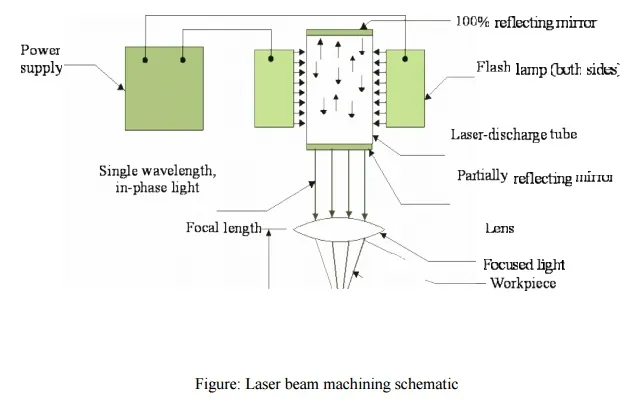

Laser-beam machining i s a thermal material-removal process that utilizes a high-energy, Coherent light beam to melt and vaporize particles on the surface of metallic and non-metallic work pieces. Lasers can be ussed to cut, drill, weld and mark. LBM is particularly suitable for making accurately placed hol es. A schematic of laser beam machining is s hown in Figure

Different types of lasers are a vailable for manufacturing operations which are as follows:

• CO2 (pulsed or continuous wave): It is a gas laser that emits light in the infrared region. It can provide up to 25 kW in continuous-wave mode.

• Nd:YAG: Neodymium -doped Yttrium-Aluminum-Garnet (Y3Al5O 12) laser is a solid- state laser which can deliver light through a fibre-optic cable. It c an provide up to 50 kW power in pulsed m ode and 1 kW in continuous-wave mode.

Figure: Laser beam machining schematic

Applications

LBM can make very accurate holes as small as 0.005 mm in refractory metals ceramics, and composite material without warping the work pieces. This process is used widely for drilling

Laser beam cutting (drilling)

• In drilling, energy transferred (e.g., via Nd YAG laser) into the workpiece melts the material at the point of contact, which subsequently changes into a plasma and leaves the region.

• A gas jet (typically, oxygen) can further facilitate this phase transformation and departure of material removed.

• Laser drilling should be targeted for hard materials and hole geometries that are difficult to achieve with other methods.

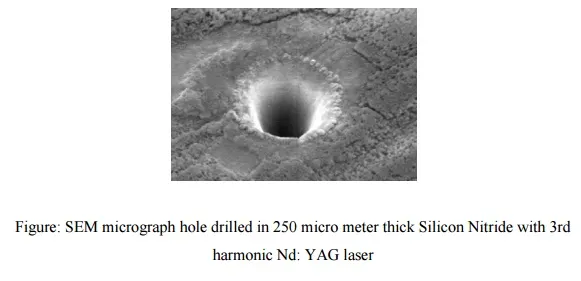

A typical SEM micrograph hole drilled by laser beam machining process employed in making a hole is shown in Figure

Figure: SEM micrograph hole drilled in 250 micro meter thick Silicon Nitride with 3rd harmonic Nd: YAG laser