Electrochemical Machining (ECM)

Introduction

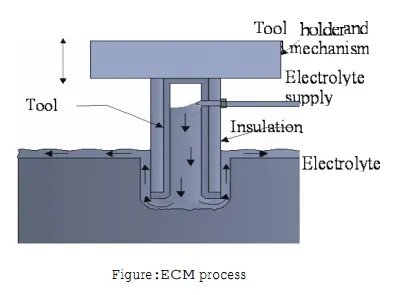

Electrochemical machin ing (ECM) is a metal -removal process base d on the principle of reverse electroplating. In this p rocess, particles travel from the anodic material (workpiece) toward the cathodic material (machining tool). A current of electrolyte fluid carries away the depleted material before it has a chance to reach the machining tool. The cavity produced is the female mating image of the tool shape.

Figure:ECM process

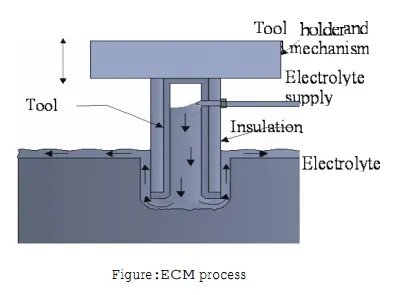

Similar to EDM, the work piece hardness is not a factor, making ECM su itable for machining difficult-to –machine materials. Difficult shapes can be made by this process o n materials regardless of their hardness. A schematic r epresentation of ECM process is shown in Figure. The ECM tool is positioned very close to the work piece and a low voltage, high amperage DC c urrent is passed between the work piece and electrode. Some of the shapes made by ECM proc ess is shown in Figure.

Figure: Parts made by ECM

Advantages of ECM

• The components are not subject to either thermal or mechanical stress.

• No tool wears during ECM process.

• Fragile parts can be machined easily as there is no stress involved.

• ECM deburring can debur difficult to access areas of parts.

• High surface finish (up to 25 µm in) can be achieved by ECM process.

• Complex geometrical shapes in high-strength materials particularly in the aerospace industry for the mass production of turbine blades, jet-engine parts and nozzles can be machined repeatedly and accurately.

• Deep holes can be made by this process.

Limitations of ECM

• ECM is not suitable to produce sharp square corners or flat bottoms because of the tendency for the electrolyte to erode away sharp profiles.

• ECM can be applied to most metals but, due to the high equipment costs, is usually used primarily for highly specialized applications.

Material removal rate, MRR, in ECM

MRR = C .I. h (cm3/min)

C: specific (material) removal rate (e.g., 0.2052 cm3/amp-min for nickel); I: current (amp);

h: current efficiency (90–100%).

The rates at which metal can electrochemically remove are in proportion to the current passed through the electrolyte and the elapsed time for that operation. Many factors other than Current influence the rate of machining. These involve electrolyte type, rate of electrolyte flow, and some other process conditions.