Figure:212

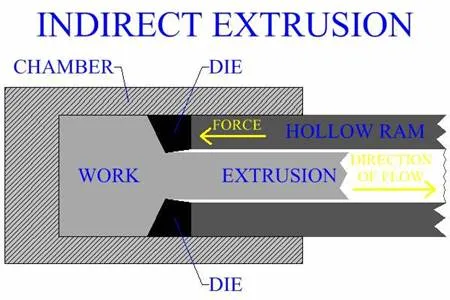

Indirect Extrusion

Indirect extrusion is a particular type of metal extrusion process in which the work piece is located in a chamber that is completely closed off at one side. The metal extrusion die are located on the ram, which exerts force from the open end of the chamber. As the manufacturing process proceeds, the extruded product flows in the opposite direction that the ram is moving. For this purpose the ram is made hollow, so that the extruded section travels through the ram itself. This manufacturing process is advantageous in that there are no frictional forces between the work piece and the chamber walls. Indirect extrusion does present limitations. Tooling and machine set up are more complicated, hollow rams are not as strong and less ridged and support of the length of the metal extrusion's profile, as it travels out of the mold, is more difficult.

Figure:212 |

Indirect extrusion can also be used to produce hollow parts. In this process, a ram is forced into the work material. The ram gives the internal geometry to the tubular part, while the material is formed around it. Difficulties in supporting the ram limit this process and the length of tubular metal extrusions that may be manufactured.

Figure:213 |