Figure:209

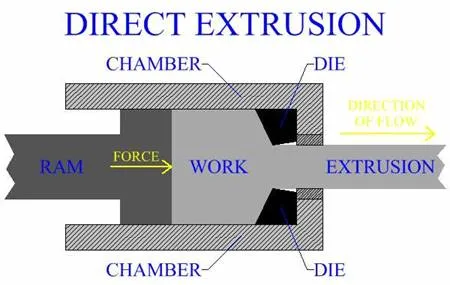

Direct Extrusion

Direct extrusion is a similar metal extrusion process to the one illustrated in figure 208. In direct, or forward extrusion, the work billet is contained in a chamber. The ram exerts force on one side of the work piece, while the forming die, through which the material is extruded, is located on the opposite side of the chamber. The length of extruded metal product flows in the same direction that the force is applied.

Figure:209 |

During direct extrusion, metal flow and forces required are affected by the friction between the work piece and the chamber walls. Particularly in hot working, oxide scale build up on the outer surfaces of the work piece can negatively influence the operation. For these reasons, it is common manufacturing practice to place a dummy block ahead of the ram. The dummy block is of slightly smaller diameter than the chamber and work piece. As the metal extrusion proceeds, the outermost surface of the work is not extruded and remains in the chamber. This material will form a thin shell, (called skull), that will latter be removed. Much of the skull will be comprised of the surface layer of oxidized scale from the work metal.

Figure:210 |

Hollow, or semi hollow, parts can be directly extruded with the use of a mandrel attached to the dummy block. A hole is created through the work, parallel to the axis over which the ram applies the force to form the extrusion. The mandrel is fitted within this hole. Once the operation begins, the ram is forced forward. The extruded metal flows between the mandrel and the die surfaces, forming the part. The interior profile of the metal extrusion is formed by the mandrel, while the exterior profile is formed by the extruding die.

Figure:211 |