Figure:208

Metal Extrusion

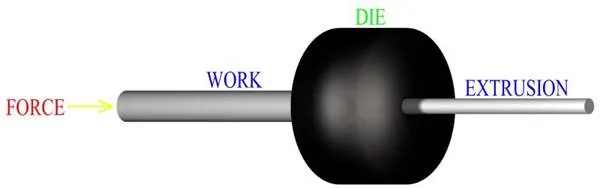

Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming the work to the new cross section. The length of the extruded part will vary, dependant upon the amount of material in the work piece and the profile extruded. Numerous cross sections are manufactured by this method. The cross section produced will be uniform over the entire length of the metal extrusion. Starting work is usually a round billet, which may be formed into a round part of smaller diameter, a hollow tube, or some other profile. The basic principle of metal extrusion is illustrated in figure 208.

Figure:208 |

In this case, a round billet is forced through a die opening creating a round part of reduced diameter. The ram will continue to move forward, pushing more of the billet material through the die opening. As this occurs, a continuous length of work will emerge from the other side of the mold at a certain velocity relative to the speed of the ram. When manufacturing an extruded product, considerations to support and guide the length of material as it exits the die are important. As the ram reaches the end of its stroke, a small portion of the billet stock can not be pushed through the die opening. This last part of the work metal is called the butt end. The product is cut at the die opening to remove it from the butt end material. In manufacturing industry, methods have been developed to extrude a wide variety of different materials. Some materials are better suited for extrusion manufacture than others. Aluminum is an extremely good material for metal extrusion. Copper, magnesium, zinc, tin and some softer low carbon steels, can also be extruded with little complication due to the material. High carbon steels, titanium and various refractory alloys, can be difficult to extrude.

Extrusion is capable of creating tremendous amounts of geometric change and deformation of the work piece, more than other metal forming processes. Metal extrusion tends to produce an elongated grain structure, usually considered favorable, in the part's material in the direction that the work is extruded. Extrusion, in many instances, can be considered a semi continuous manufacturing operation. Continuous because the process will manufacture a continuous length of the same cross section. From this length, individual discrete parts can be cut. It is semi continuous and not completely continuous, (such as continuous casting), because the length of extruded product is still limited by the amount of material in the work piece. The work piece must be reloaded at the end of every cycle. Metal extrusion can also be a discrete manufacturing process, producing a single part with every cycle. As in other metal forming operations, the forces involved and the material flow patterns that occur during extrusion are of primary concern in the analysis and development of this manufacturing process. The many factors that affect metal flow will be discussed.