Figure 1

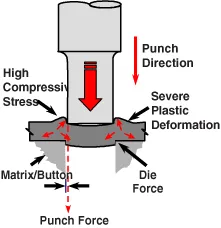

When a punch makes contact with the sheet, the metal begins to deform and bulge around the point of the punch. Image courtesy of Dayton Progress.

|

Figure 1 |

Fineblanking is a specialty type of metal stamping that can achieve part characteristics such as flatness and a full sheared edge to a degree that is nearly impossible using a conventional metal cutting or punching process.

In fineblanking, the manufactured product needs to have a full contact surface on the edge of the part. As an example, a gear, which often requires critical flatness and must have every tooth fully engaged with the gear that it mates to throughout the entire thickness of the part, is an ideal candidate for fineblanking.

Fineblanking also can pierce very small holes with respect to the metal thickness, as well as holes very close to the edge of the part and close to other holes.

Fineblanking is easier to understand if you also understand what takes place during conventional metal punching.

The first thing to remember is that all metals have a particular elastic behavior. During conventional punching, the metal deforms upon initial punch contact. Figure 1shows the first step in piercing or cutting a hole in a piece of sheet metal.

![]()

When the punch makes contact with the sheet, the metal begins to deform and bulge around the point of the punch. As the yield strength of the part material is exceeded by the downward force of the press, the point of the punch begins to penetrate the metal's surface. Both the punch and matrix, or button, begin to cut from their respective sides.

When the ultimate tensile strength has been reached, the metal breaks or fractures from the edge of the punch to the edge of the matrix. This results in a cut edge that appears to be partially cut and partially broken or fractured. This cut edge condition often is referred to as the "cut band."

In most cases, the cut edge has about 10 percent to 30 percent of shear, and the remainder is fractured. The fracture has two primary causes:

Allowing the metal to deform severely during the cutting process results in straining of the metal, which in turn causes stress. Trapped stresses in a product cause it to lose its flatness, which is why it is very difficult to maintain a critical flatness characteristic using conventional methods.

Figure 2shows a cut band created with a conventional metal punching process. The cut surface is partially angled and has a rough appearance in the fracture zone of the cut.

|

Figure 2 |

Fineblanking requires the use of three very high-pressure pads in a special press. These pads hold the metal flat during the cutting process and keep the metal from plastically deforming during punch entry.

Most fineblanking operations incorporate a V-ring into one of the high-pressure pads. This ring also is commonly referred to as a "stinger" or "impingement" ring. Before the punch contacts the part, the ring impales the metal, surrounds the perimeter of the part, and traps the metal from moving outward while pushing it inward toward the punch. This reduces rollover at the cut edge.

Fineblanking operations usually require clearances of less than 0.0005 inch per side. This small clearance, combined with high pressure, results in a fully sheared part edge.

Fineblanking is much like a cold extruding process. The slug (or part) is pushed or extruded out of the strip while it is held very tightly between the high-pressure holding plates and pads. The tight hold of the high-pressure plates prevents the metal from bulging or plastically deforming during the extrusion process.

|

Figure 3 |

Figure 3shows a fineblanking process and a conventional punching process. Figure 4shows parts made from both processes.

|

Figure 4 |

Fineblanking can obtain part flatness that is nearly impossible to achieve with conventional processes. It can create 100 percent sheared edges with 90-degree angles, and dimensional accuracy often is equal to that obtained with machining.

Fineblanking can be used on a variety of metals, including tool steel. It also is suitable for use on heavy metals up to 0.625 in. thick, even for making small holes.

The process is relatively fast; parts can be run progressively, and coining and embossing can be incorporated into the process.

Because of the small clearances needed, fineblanking can cause severe tool wear, so premium tool steels with coatings or carbide often are required. Because the V-ring requires space, more material usually is required to make the part as well.

Burrs on fineblanked parts typically are larger than those on conventionally punched parts, so deburring often is required.

Finally, the initial investment in fineblanking equipment can be substantial. Stampers new to the process might consider outsourcing fineblanking services as an introduction to the technology before taking on such a large investment.