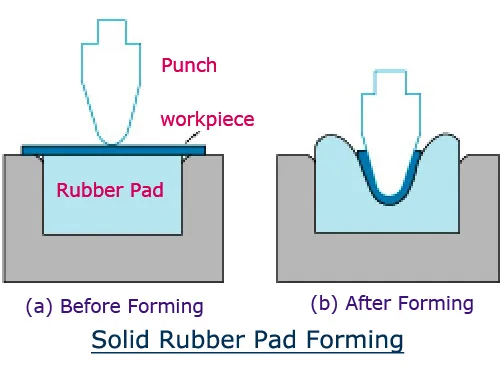

The rubber pad forming process is also called as “guerin” process. The die is placed on lower bed and top of that soft die of rubber is placed. The rubber die is forced on the blank and deform the blank into require shape. During the rubber pad forming process, the punch deforms the blank and apply large pressure (100 Mpa) over the blank. The punch is act universal tool, which is used to provide various different parts. The rubber pad forming sheet metal parts having without stress.

It is easy and requires application of rigid container fillet with solid rubber pad.

The blank of sheet metal work piece is placed on the die. Before the forming process, the blanks are precut to their final dimension.

The punch become downward the presses the work blank again the rubber pad. So, the work metal is forced on the punch. So the form of punch is obtained on the sheet metal. The rubber pad in one side of blank to minimize the friction between the die and blank, so the damage and wrinkling of blank will be avoided during the pad forming process. The male or female dies are used. The male die is used to make a flanged parts. The female die is used for making a deep drawn parts, that complexity will be less. After complete forming the part have to be trimming to their require final dimension.

· The soft rubber placed on the top punch and will not damage or scratch the sheet metal.

· Accurate and time consuming of die is not necessary.

· That require only one punch to manufacture of sheet metal.

· The special surface layer such as clad layers.

· Any of shape can be formed in one process cycle

· Tooling cost will be low

· Uniform pressure to apply over the surface of blank.

·

· Require long time

· Limit the number of parts

· Large force required

· Soft tool is deformed during the process.

· Complex shape part formed limited

· The soft tool is wear also.

· Flanged parts and deep drawn parts

· Steel alloys

· Air craft industry

· Aluminium alloy