High Energy Rate Forming

High energy rate forming is the forming of sheet metal by a high energy surge, delivered over a very short time. Since the forming of the metal occurs so quickly, desirable materials for (HERF) will be ductile at high deformation speeds.

Explosives can deliver a huge amount of power. Although most explosive detonations are destructive, the power from an explosive charge can be used to manufacture parts. An explosive forming process commonly used for the production of large parts is called a standoff system. Typically the mold and work piece are submerged in water. The sheet metal is secured over the mold by a ring clamp. Air is drawn out, creating a vacuum in the die cavity. An explosive is placed between the die cavity and the work, a certain distance from the work. This distance is called the standoff distance. Standoff distance depends on the size of the work, for larger parts it is usually about half the diameter of the blank. The explosive itself is also deeply submersed in water. Upon detonation, the shock wave travels through the water and delivers great energy to the work, forming it to the die cavity near instantaneously. This high energy rate forming process can be used to form big thick plates.

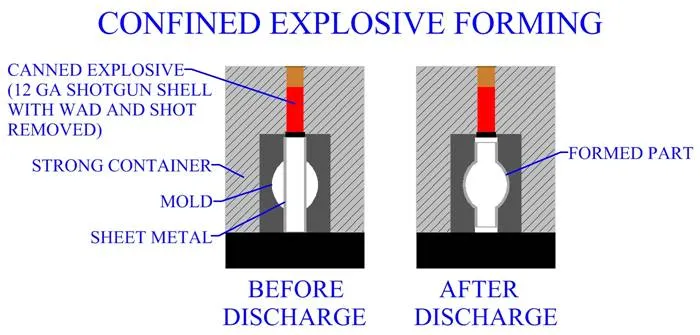

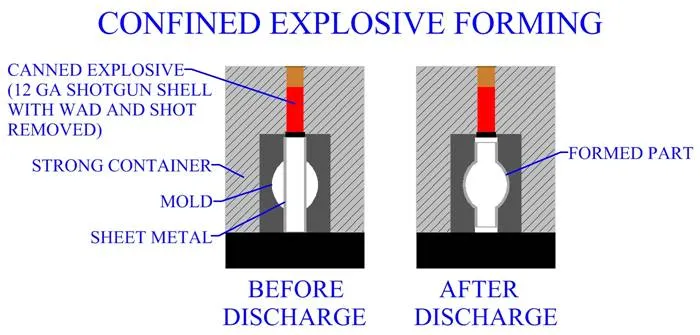

Explosive forming has a long cycle time and is suitable for low quantity production of large, unique parts. Mechanical properties imparted to the material as a result of the explosive forming process are similar to mechanical properties imparted to work manufactured by other forming processes. Molds can be made out of inexpensive or easy to shape materials, or molds can be made more permanent. Materials for molds include aluminum, wood, concrete, plastic, iron and steel. If a mold is manufactured from a material such as plastic, the low modulus of elasticity will greatly reduce springback in the sheet metal, resulting in higher accuracy. The amount of explosive depends upon the type of system used and the amount of pressure needed to form the part. The shock wave generated by the explosive travels along an expanding spherical front. Much of the energy from the shock wave is not absorbed by the work piece. A modified setup of the standoff system uses reflectors to focus the energy surge. This provides a more effective use of power and a smaller explosive can be used to form the same part. Another system called a confined system, uses a canned explosive or cartridge. This is usually used for relatively smaller parts than the standoff system. All of the energy is directed into a closed container, the walls of which contain the die cavity. The energy from the canned explosive forces the sheet metal into the walls of the mold, forming the part. Safety is always a consideration when manufacturing by explosive forming, particularly with the confined system, where die failure is a significant concern. |

|

|

|

| Electrohydraulic FormingElectrohydraulic forming, also called electric discharge forming, is a unique high energy forming process for sheet metal. This manufacturing process uses the energy from the combustion of a thin metal wire. Two electrodes, with a wire connecting them, are submersed in liquid. The work is set up similar to the standoff system described above, however this process is applicable to relatively smaller parts. A sheet metal blank is secured on top of the mold with a ring clamp and a vacuum is created in the die cavity under the blank. Electrical energy is stored in a capacitor bank. The electricity is discharged through the electrodes and the wire, instantly vaporizing the wire, creating a shock wave that travels through the water. This shock wave forms the sheet metal to the mold cavity. Electrohydraulic forming produces a shock wave of relatively low magnitude and is best suited for thinner work. The wire needs to be replaced after every operation. Electrohydraulic forming may be considered to have a low production rate. |

|

|

|

| Electromagnetic FormingElectromagnetic forming is a popular high energy rate forming process that uses a magnetic surge to form a sheet metal part. In the electromagnetic process, also called magnetic pulse forming, an electric coil is placed near a metal work piece. A capacitor bank is charged up and a large electrical surge is sent through the coil. The current creates a magnetic field. When a conductive material disrupts a magnetic field it produces a current in that material, this is called an eddy current. Due to the close proximity of the conductive sheet metal to the coil, the coil's magnetic field is disrupted and eddy currents are generated in the work piece. These currents in the sheet metal produce their own magnetic field that opposes the original magnetic field of the coil. The opposing forces push these fields apart and form the work. The coil may be placed inside or over the work, depending upon the desired effect. Many electromagnetic forming operations are used to bulge tubes, or form tubes over other parts such as rods and cables. Electromagnetic forming is used for relatively thinner sheet metal parts. |

|

|

|

|