INVOLUTE GEAR PROFILE

Imagine pulleys with simple indentations on their periphery equally spaced by pitch.

These pulleys, when moved, would :

· slip at the contact point

· not rotate smoothly

· produce vibration and noise

They are improperly suited for use as gears. Satisfactory gears must transmit power smoothly by rolling action. The involute curve meets all the requirements for a gear-tooth profile.

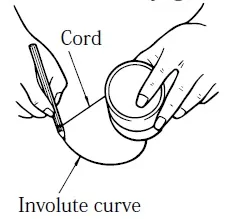

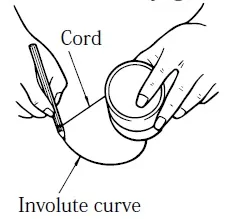

The involute curve

If a cord is wrapped around a cylinder, as shown in this figure, a point on the cord, as it is unwrapped from the cylinder, traces a curve called an involute.

The circle from which the string is unwound is called the base circle.

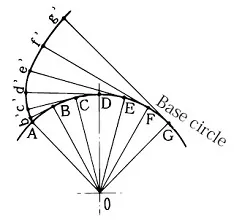

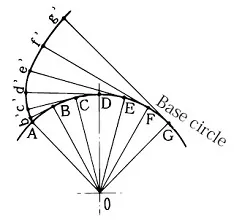

Let us try to make a simple drawing of an eight-toothed gear :

First, divide a cylinder into eight equal parts. Then, from each part unwrap a cord drawing a line with a pencil.

After you have completed eight lines, do the same manual work from the opposite side.

The diagram thus drawn is the involute tooth profile.

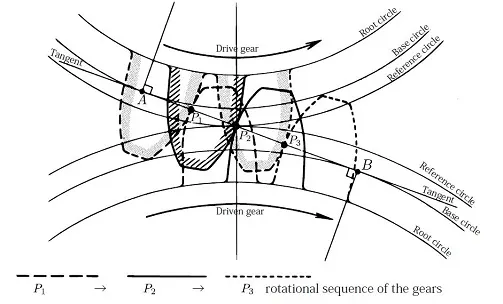

This figure indicates how two involute teeth in mesh are moving to transmit rotary motion.

Important terminologies in this figure :

· Tangent

· Root circle

· Base circle

· Reference circle

· Drive gear

· Driven gear

Rotational sequence of the gears : P1 -> P2 -> P3

When Gear 1 drives Gear 2 by acting at the instantaneous contact point, the contact point moves on the common tangent in the order of P1 -> P2 -> P3.

You can see that the contact point rolls along the involute curves of the gears. Moreover, the points P1, P2 and P3 lie on the common tangent to the two base circles.

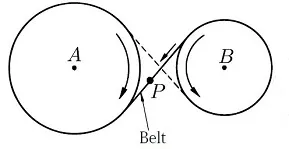

It is similar to the point, P, on a criss-crossed belt as the disks rotate.

In effect, the involute shape of the gear teeth allows the contact point to move smoothly, transmitting the motion. Therefore, the involute curve is the ideal shape for gear teeth.

Features :

· Conjugate action is relatively independent of small errors in center distance

· Can be manufactured at low cost since the tooth profile is relatively simple

· Its root thickness makes it strong

· A typical tooth profile used almost exclusively for gears