Cams

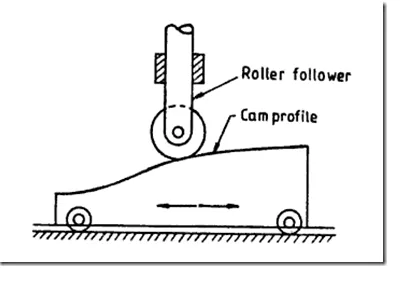

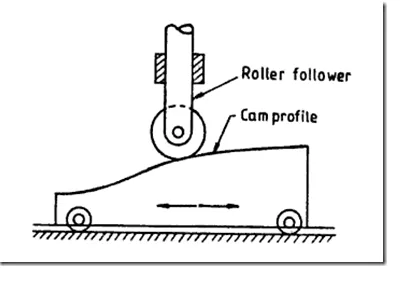

A cam is a mechanical member used to produce desired motion to a follower by direct contact. The cam may be rotating or reciprocating whereas the follower may be rotating, reciprocating or oscillating.

Difference between Oscillating motion and Reciprocating Motion

One of the few doubts which arise in the mind of the student is the difference between oscillating and reciprocating motions. The difference between oscillating motion and reciprocating motion is that the oscillating motion follows the equation of Simple Harmonic Motion. We will discuss the details of simple harmonic motion in some other article but right now our definition is that simple harmonic motion is the motion which follows sinusoidal curve. i.e. which is according to the equation X=ASin(wt). Any to and fro motion is known as reciprocating motion. More precise, the definitions are:

Oscillation:

Oscillation, repeating back-and-forth motion, is very common in nature. Often we think of "Simple Harmonic Oscillation" as a motion which varies sinusoidally with time: Many, many systems oscillate in this way, from a plucked string to a ringing bell, to radio waves (x is an electric field, say), and lots of other stuff. Even things that don’t move back and forth can oscillate.

Reciprocation:

"Reciprocation" is most often used to refer to motion that is repetitive and involves some kind of back-and-forth changing of the position. I wouldn’t demand that the position vary sinusoidally with time to say that it is reciprocating (although that is nearly the case with common objects in reciprocating motion). Examples include pistons in pumps and steam engines on trains as things that reciprocate. Reciprocating saws have a straight saw blade that is driven up and down with a motor.

Complicated output motions which are otherwise difficult to achieve can easily be produced with the help of cams. Cams are widely used in automatic machines, internal combustion engines, machine tools, printing control mechanisms, and so on. They are manufactured usually by die-casting, milling or by punch-presses.

A cam and follower pair is always a higher pair. i.e. it must have either line or point contact and not the surface contact. The necessary elements of a cam-follower system are:

Design of cams:

Cams are widely used in almost all machinery. They include internal combustion engines, a variety of machine tools, compressors and computers. In general, a cam can be designed in two ways.

The latter procedure simplifies the manufacturing process, and this is why most of the cams are designed in this manner. However, if a particular motion is desired for the performance of a machine, the first procedure is to be adopted.

The cam design is usually simple for low-speed machinery. Although a cam may be designed to impart a particular motion to the follower, certain motions give rise to large velocities, accelerations and jerks over a cycle which will produce high stresses and undue vibration in the machine assembly. These problems are more pronounced for high-speed cams. In such cases the design of a cam is more complicated.