Mechanical Properties of Titanium Alloys

Unalloyed, commercially pure titanium has a tensile strength ranging from 275 to 590 MPa, and this strength is controlled primarily through oxygen content

and iron content. The higher the oxygen and iron content, the higher the

strength. Commcercially alloyed titanium grades can range from a tensile strength as low as 600 MPa ( such as Ti-3A1-2.5V) to a tensile strength as high as 1250 MPa ( e.g. for the high strength alloy Ti-15Mo-5Zr-3AI).

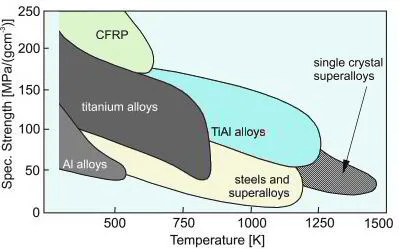

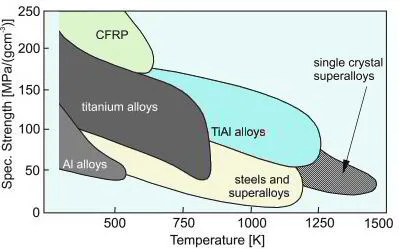

Commercially pure titanium is stable up to temperatures of approximately 300°C due to its specific strength and creep resistance. More complex titanium alloys exhibit high strength even at temperatures up to approximately 500°C.

The fatigue strength (10^7 cycles) is roughly equivalent to 50% of the tensile

strength, and welding does not cause a significant decline in fatigue strength. Even in seawater, both commercially pure titanium and titanium alloys exhibit almost no decline in fatigue strength.

The fracture toughness of titanium alloys range from 28 to 108 MPa m^1/2

and is in negative correlation with tensile yield strength. The specific fracture toughness is dependent on microstructure, and thus fracture toughness of the various alloys is higher in Titanium alloys with acicular structures.

Microstructure design and mechanical properties in a near-alpha Ti–4Mo alloy

Acta Materialia 97 (2015) 291-304

Microstructure design and mechanical properties in a near-a Ti–4Mo alloy

Z. Tarzimoghadam, S. Sandlöbes, K.G. Pradeep, D. Raabe

Acta Materialia 97 (2015) 291 Ti Mo Micr[...]

PDF-Dokument [3.8 MB]

Mechanical Properties of Titanium Alloys (image from: Titanium and Titanium Alloys. Fundamentals and Applications. eds. Leyens, Peters)

Mechanical Properties of Titanium Alloys (image from: Titanium and Titanium Alloys. Fundamentals and Applications. eds. Leyens, Peters)

Mechanical Properties of some Titanium Grades and Alloys

Tensile strength (min) | 0.2% yield strength (min) | |||

Designation | MPa | ksi | MPa | ksi |

Unalloyed grades |

|

| ||

ASTM grade 1 | 240 | 35 | 170 | 25 |

ASTM grade 2 | 340 | 50 | 280 | 40 |

ASTM grade 3 | 450 | 65 | 380 | 55 |

ASTM grade 4 | 550 | 80 | 480 | 70 |

ASTM grade 7 | 340 | 50 | 280 | 40 |

ASTM grade 11 | 240 | 35 | 170 | 25 |

α and near-α alloys |

|

| ||

Ti-0.3Mo-0.8Ni | 480 | 70 | 380 | 55 |

Ti-5Al-2.5Sn | 790 | 115 | 760 | 110 |

Ti-5Al-2.5Sn-ELI | 690 | 100 | 620 | 90 |

Ti-8Al-1Mo-1V | 900 | 130 | 830 | 120 |

Ti-6Al-2Sn-4Zr-2Mo | 900 | 130 | 830 | 120 |

Ti-6Al-2Nb-1Ta-0.8Mo | 790 | 115 | 690 | 100 |

Ti-2.25Al-11Sn-5Zr-1Mo | 1000 | 145 | 900 | 130 |

Ti-5.8Al-4Sn-3.5Zr-0.7Nb-0.5Mo-0.35Si | 1030 | 149 | 910 | 132 |

α-β alloys |

|

| ||

Ti-6Al-4V(a) | 900 | 130 | 830 | 120 |

Ti-6Al-4V-ELI(a) | 830 | 120 | 760 | 110 |

Ti-6Al-6V-2Sn(a) | 1030 | 150 | 970 | 140 |

Ti-8Mn(a) | 860 | 125 | 760 | 110 |

Ti-7Al-4Mo(a) | 1030 | 150 | 970 | 140 |

Ti-6Al-2Sn-4Zr-6Mo(b) | 1170 | 170 | 1100 | 160 |

Ti-5Al-2Sn-2Zr-4Mo-4Cr(b)(c) | 1125 | 163 | 1055 | 153 |

Ti-6Al-2Sn-2Zr-2Mo-2Cr(c) | 1030 | 150 | 970 | 140 |

Ti-3Al-2.5V(d) | 620 | 90 | 520 | 75 |

Ti-4Al-4Mo-2Sn-0.5Si | 1100 | 160 | 960 | 139 |

β alloys |

|

| ||

Ti-10V-2Fe-3Al(a)(c) | 1170 | 170 | 1100 | 160 |

Ti-13V-11Cr-3Al(b) | 1170 | 170 | 1100 | 160 |

Ti-8Mo-8V-2Fe-3Al(b)(c) | 1170 | 170 | 1100 | 160 |

Ti-3Al-8V-6Cr-4Mo-4Zr(a)(c) | 900 | 130 | 830 | 120 |

Ti-11.5Mo-6Zr-4.5Sn(a) | 690 | 100 | 620 | 90 |

Ti-15V-3Cr-3Al-3Sn | 1000(b) | 145(b) | 965(b) | 140(b) |

| 1241(f) | 180(f) | 1172(f) | 170(f) |

Ti-15Mo-3Al-2.7Nb-0.2Si |

|

|

|

|