What is tool steel ?

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation and their ability to hold a cutting edge at elevated temperatures. As a result tool steels are suited for their use in the shaping of other materials.

There are six groups of tool steel: water-hardening, cold-work tool steels, shock-resisting, high-speed, hot-work, and special purpose/plastic mold tools steel. The choice of group to select depends on, cost, working temperature, required surface hardness, strength, shock resistance, and toughness requirements. The more severe the service condition (higher temperature, abrasiveness, corrosiveness, loading), the higher the alloy content and consequent amount of carbides required for the tool steel.

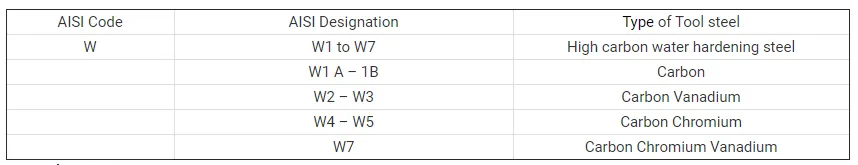

1. Water-hardening group

Named from its essential property of having to be water quenched. This group of tool steel is essentially plain high carbon steel. It is commonly used because of its low cost.

W-group tool steel gets its name from its defining property of having to be water quenched. W-grade steel is essentially high carbon plain-carbon steel. This group of tool steel is the most commonly used tool steel because of its low cost compared to others. They work well for small parts and applications where high temperatures are not encountered; above 150 °C (302 °F) it begins to soften to a noticeable degree. Its hardenability is low, so W-group tool steels must be subjected to a rapid quenching, requiring the use of water. These tool steels can attain high hardness (above HRC 66) and are rather brittle compared to other tool steels. W-steels are still sold, especially for springs, but are much less widely used than they were in the 19th and early 20th centuries. This is partly because W-steels warp and crack much more during quench than oil-quenched or air hardening steels.

2. Cold-work group

This is a group of three tool steels: oil-hardening, air-hardening, and high carbon-chromium. The steels in the group have high hardenability and wear resistance, with average toughness. Typically they are in the production of larger parts or parts that have a minimum distortion requirement when being hardened.

Both Oil quenching and Air-hardening both reduce the distortion and higher stress caused by the quick water quenching.Because of this they are less likely to crack.

A very common oil hardening steel is O1 steel. It is a very good cold work steel and also makes very good knives and forks. It can be hardened to about 57-61 HRC.

The first air-hardening grade tool steel was mushet steel, which was known as air-hardening steel at the time.

Modern air-hardening steels are characterized by low distortion during heat treatment because of their high-chromium content. Their machinability is good and they have a balance of wear resistance and toughness (i.e. between the D- and shock-resistant grades).

2.3.1. D-type

The D-type, of the cold-work class of tool steels, contain between 10% and 13% chromium. These steels retain their hardness up to a temperature of 425 °C (797 °F). Common applications for these tool steels include forging dies, die-casting die blocks, and drawing dies. Due to their high chromium content, certain D-type tool steels are often considered stainless or semi-stainless, however their corrosion resistance is very limited due to the precipitation of the majority of their chromium and carbon constituents as carbides.

D2 Tool Steel is very wear resistant but not as tough as lower alloyed steels. The mechanical properties of D2 are very sensitive to heat treatment. It is widely used for the production of shear blades, planer blades and industrial cutting tools; sometimes used for knife blades.

ISO 1.2767, also known as DIN X 45 NiCrMo 4, AISI 6F7, and BS EN 20 B, is an air-hardening tool steel with a primary alloying element of nickel. It possesses good toughness, stable grains, and is highly polishable. It is primarily used for dies in plastic injection molding application that involve high stresses. Other applications include blanking dies, forging dies, and industrial blades.

The following steel grades are also in cold work steel group.

3. Shock-resisting group

This class has high shock resistance and good hardenability. It is designed to resist shock at both low and high temperatures. It also has a very high impact toughness and relatively low abrasion resistance.

Carbide-forming alloys provide the necessary abrasion resistance, hardenability, and hot-work characteristics. This family of steels displays very high impact toughness and relatively low abrasion resistance and can attain relatively high hardness (HRC 58/60). In the US, toughness usually derives from 1 to 2% silicon and 0.5-1% molybdenum content. In Europe, shock steels often contain 0.5-0.6 % carbon and around 3% nickel. 1.75% to 2.75% nickel is still used in some shock resisting and high strength low alloy steels (HSLA), such as L6, 4340, and Swedish saw steel, but it is relatively expensive. An example of its use is in the production of jackhammer bits.

4. High speed group

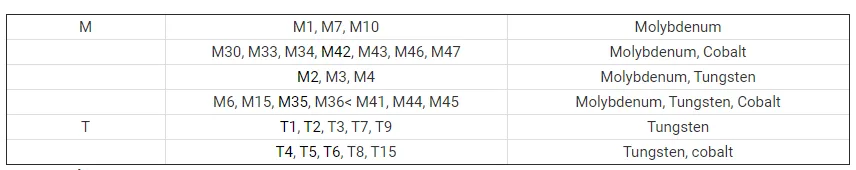

T-type and M-type tool steels are used for cutting tools when strength and hardness must be retained at high temperatures.

High-speed steel (HSS or HS) is a subset of tool steels, commonly used in tool bits and cutting tools. It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high-speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and abrasion resistance (generally linked to tungsten and vanadium content often used in HSS) compared with common carbon and tool steels.

5. Hot-working group

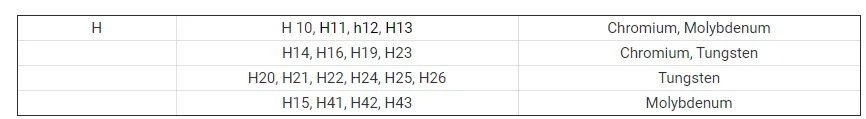

H-group tool steels were specifically developed to maintain strength and hardness while exposed to prolonged elevated temperatures.

Hot-working steels are a group of steel used to cut or shape material at high temperatures. H-group tool steels were developed for strength and hardness during prolonged exposure to elevated temperatures. These tool steels are low carbon and moderate to high alloy that provide good hot hardness and toughness and fair wear resistance due to a substantial amount of carbide. H1 to H19 are based on a chromium content of 5%; H20 to H39 are based on a tungsten content of 9-18% and a chromium content of 3–4%; H40 to H59 are molybdenum based.

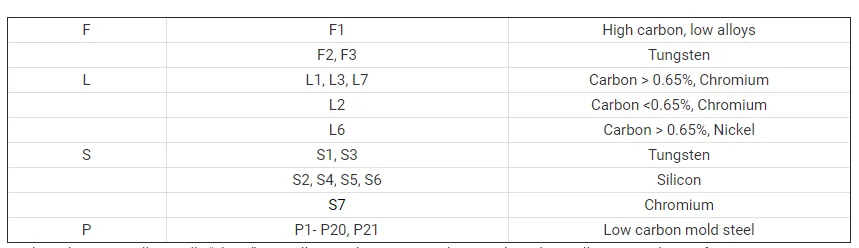

6. Special purpose group / Plastic Mold Steel

P-type tool steel is short for plastic mold steels. They are designed to meet the requirements of zinc die casting and plastic injection molding dies. Common steel grades like P20, 420 etc.

L-type tool steel is short for low alloy special purpose tool steel. L6 is extremely tough.

F-type tool steel is water hardened and substantially more wear resistant than W-type tool steel.

Tool steels are metallurgically “clean,” high-alloy steels that are melted in relatively small heats in electric furnaces and produced with careful attention to homogeneity. They can be further refined by argon/oxygen decarburization (AOD), vacuum methods, or electroslag refining (ESR). As a result, tool steels are often specified for critical high-strength or wear-resistant applications. Because of their high alloy content, tool steels must be rolled or forged with care to produce satisfactory bar products.

To develop their best properties, tool steels are always heat treated. Because the parts may distort during heat treatment, precision parts should be semifinished, heat treated, then finished. Severe distortion is most likely to occur during liquid quenching, so an alloy should be selected that provides the needed mechanical properties with the least severe quench.