MARTEMPERING AND AUSTEMPERING

It will be readily appreciated that the quenching operation used in hardening introduces internal stresses into the steel. These can be sufficiently large to distort or even crack the steel.

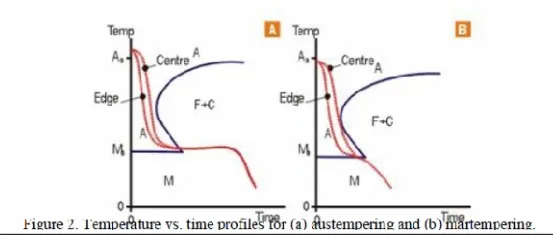

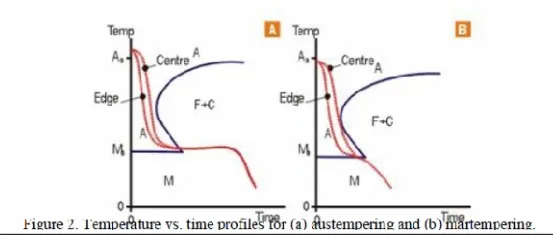

Martempering is applied to steels of sufficient hardenability and involves an isothermal hold in the quenching operation. This allows temperature equalisation across the section of the part and more uniform cooling and structure, hence lower stresses. The steel can then be tempered in the usual way.

Austempering also invo lves an isothermal hold in the quenching operation, but the structure formed, whilst hard and tough, does not require further tempering. The process is mostly applied to high carbon steels in relatively thin sections for springs o r similarparts . These processes are shown schematically in the TTT Curves, (figures 2a and 2b). there is sufficient heat sink in the part and an external quench is not needed. There is a much lower risk of distortion associated with this practice, and it can be highly automated and it is very reproducible

Body - the case walls must combine flexibility and strength to contribute to the obturati on system.

Mouth - must be softer (larger brass grains) to prevent cracks from the strain of holding a bullet.