Open-loop System

The open-loop configuration does not monitor or measure the condition of its output signal as there is no feedback

In the previous tutorial about Electronic Systems, we saw that a system can be defined as a collection of subsystems which direct or control an input signal to produce the desired output condition.

The function of any electronic system is to automatically regulate the output and keep it within the systems desired input value or “set point”. If the systems input changes for whatever reason, the output of the system must respond accordingly and change itself to reflect the new input value.

Likewise, if something happens to disturb the systems output without any change to the input value, the output must respond by returning back to its previous set value. In the past, electrical control systems were basically manual or what is called an Open-loop System with very few automatic control or feedback features built in to regulate the process variable so as to maintain the desired output level or value.

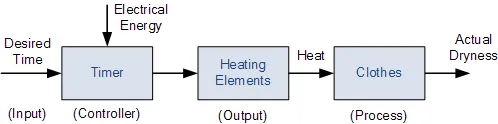

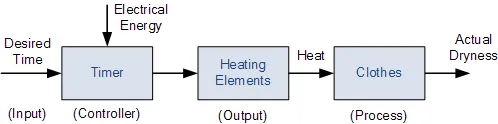

For example, an electric clothes dryer. Depending upon the amount of clothes or how wet they are, a user or operator would set a timer (controller) to say 30 minutes and at the end of the 30 minutes the drier will automatically stop and turn-off even if the clothes where still wet or damp.

In this case, the control action is the manual operator assessing the wetness of the clothes and setting the process (the drier) accordingly.

So in this example, the clothes dryer would be an open-loop system as it does not monitor or measure the condition of the output signal, which is the dryness of the clothes. Then the accuracy of the drying process, or success of drying the clothes will depend on the experience of the user (operator).

However, the user may adjust or fine tune the drying process of the system at any time by increasing or decreasing the timing controllers drying time, if they think that the original drying process will not be met. For example, increasing the timing controller to 40 minutes to extend the drying process. Consider the following open-loop block diagram.

Then an Open-loop system, also referred to as non-feedback system, is a type of continuous control system in which the output has no influence or effect on the control action of the input signal. In other words, in an open-loop control system the output is neither measured nor “fed back” for comparison with the input. Therefore, an open-loop system is expected to faithfully follow its input command or set point regardless of the final result.

Also, an open-loop system has no knowledge of the output condition so cannot self-correct any errors it could make when the preset value drifts, even if this results in large deviations from the preset value.

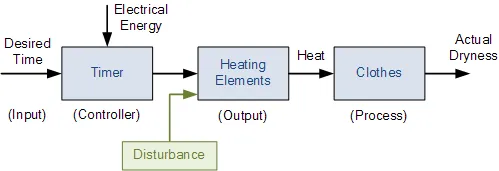

Another disadvantage of open-loop systems is that they are poorly equipped to handle disturbances or changes in the conditions which may reduce its ability to complete the desired task. For example, the dryer door opens and heat is lost. The timing controller continues regardless for the full 30 minutes but the clothes are not heated or dried at the end of the drying process. This is because there is no information fed back to maintain a constant temperature.

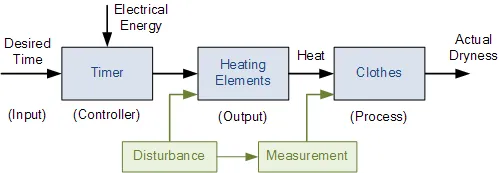

Then we can see that open-loop system errors can disturb the drying process and therefore requires extra supervisory attention of a user (operator). The problem with this anticipatory control approach is that the user would need to look at the process temperature frequently and take any corrective control action whenever the drying process deviated from its desired value of drying the clothes. This type of manual open-loop control which reacts before an error actually occurs is called Feed forward Control

The objective of feed forward control, also known as predictive control, is to measure or predict any potential open-loop disturbances and compensate for them manually before the controlled variable deviates too far from the original set point. So for our simple example above, if the dryers door was open it would be detected and closed allowing the drying process to continue.

If applied correctly, the deviation from wet clothes to dry clothes at the end of the 30 minutes would be minimal if the user responded to the error situation (door open) very quickly. However, this feed forward approach may not be completely accurate if the system changes, for example the drop in drying temperature was not noticed during the 30 minute process.

Then we can define the main characteristics of an “Open-loop system” as being:

· There is no comparison between actual and desired values.

· An open-loop system has no self-regulation or control action over the output value.

· Each input setting determines a fixed operating position for the controller.

· Changes or disturbances in external conditions does not result in a direct output change (unless the controller setting is altered manually).

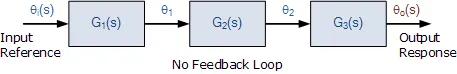

Any open-loop system can be represented as multiple cascaded blocks in series or a single block diagram with an input and output. The block diagram of an open-loop system shows that the signal path from input to output represents a linear path with no feedback loop and for any type of control system the input is given the designation θi and the output θo.

Generally, we do not have to manipulate the open-loop block diagram to calculate its actual transfer function. We can just write down the proper relationships or equations from each block diagram, and then calculate the final transfer function from these equations as shown.

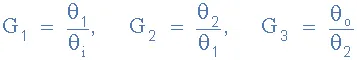

The Transfer Function of each block is therefore:

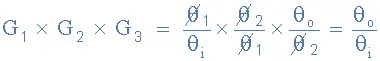

The overall transfer function is given as:

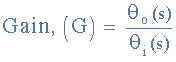

Then the Open-loop Gain is given simply as:

When G represents the Transfer Function of the system or subsystem, it can be rewritten as: G(s) = θo(s)/θi(s)

Open-loop control systems are often used with processes that require the sequencing of events with the aid of “ON-OFF” signals. For example a washing machines which requires the water to be switched “ON” and then when full is switched “OFF” followed by the heater element being switched “ON” to heat the water and then at a suitable temperature is switched “OFF”, and so on.

This type of “ON-OFF” open-loop control is suitable for systems where the changes in load occur slowly and the process is very slow acting, necessitating infrequent changes to the control action by an operator.

We have seen that a controller can manipulate its inputs to obtain the desired effect on the output of a system. One type of control system in which the output has no influence or effect on the control action of the input signal is called an Open-loop system.

An “open-loop system” is defined by the fact that the output signal or condition is neither measured nor “fed back” for comparison with the input signal or system set point. Therefore open-loop systems are commonly referred to as “Non-feedback systems”.

Also, as an open-loop system does not use feedback to determine if its required output was achieved, it “assumes” that the desired goal of the input was successful because it cannot correct any errors it could make, and so cannot compensate for any external disturbances to the system.

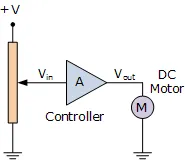

So for example, assume the DC motor controller as shown. The speed of rotation of the motor will depend upon the voltage supplied to the amplifier (the controller) by the potentiometer. The value of the input voltage could be proportional to the position of the potentiometer.

If the potentiometer is moved to the top of the resistance the maximum positive voltage will be supplied to the amplifier representing full speed. Likewise, if the potentiometer wiper is moved to the bottom of the resistance, zero voltage will be supplied representing a very slow speed or stop.

Then the position of the potentiometers slider represents the input, θi which is amplified by the amplifier (controller) to drive the DC motor (process) at a set speed N representing the output, θo of the system. The motor will continue to rotate at a fixed speed determined by the position of the potentiometer.

As the signal path from the input to the output is a direct path not forming part of any loop, the overall gain of the system will the cascaded values of the individual gains from the potentiometer, amplifier, motor and load. It is clearly desirable that the output speed of the motor should be identical to the position of the potentiometer, giving the overall gain of the system as unity.

However, the individual gains of the potentiometer, amplifier and motor may vary over time with changes in supply voltage or temperature, or the motors load may increase representing external disturbances to the open-loop motor control system.

But the user will eventually become aware of the change in the systems performance (change in motor speed) and may correct it by increasing or decreasing the potentiometers input signal accordingly to maintain the original or desired speed.

The advantages of this type of “open-loop motor control” is that it is potentially cheap and simple to implement making it ideal for use in well-defined systems were the relationship between input and output is direct and not influenced by any outside disturbances. Unfortunately this type of open-loop system is inadequate as variations or disturbances in the system affect the speed of the motor. Then another form of control is required.

In the next tutorial about Electronics Systems, we will look at the effect of feeding back some of the output signal to the input so that the systems control is based on the difference between actual and desired values. This type of electronics control system is called Closed-loop Control.