Convert rotary motion into linear motion

Lead screws are a common technology used to convert rotary motion into linear motion, and are often used to provide actuation to a set of linear bearings. Plastic lead screw nuts are an excellent alternative to ball screws in many applications where extreme precision (micron level) is not required. They require no external lubricant, which makes them suitable in applications ranging from sensitive lab instruments to packaging machines. Trapezoidal lead screws are ideal for 3D printers, as the industry is standardized on metric motion profiles and components. They are also very easy to customize, and are found in a number of geometries, from coarse threads for higher torque output, to high-helix designs for higher speed applications.

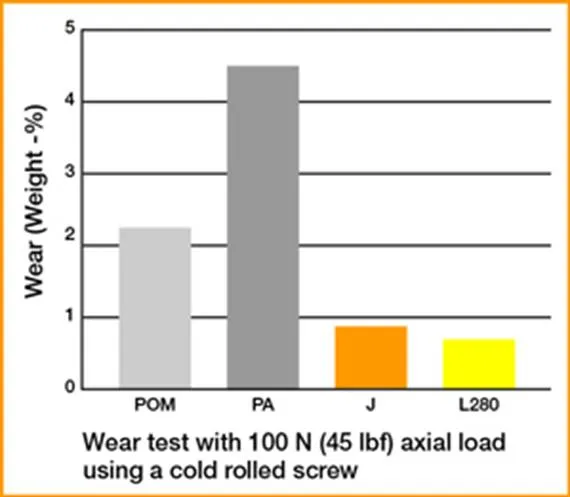

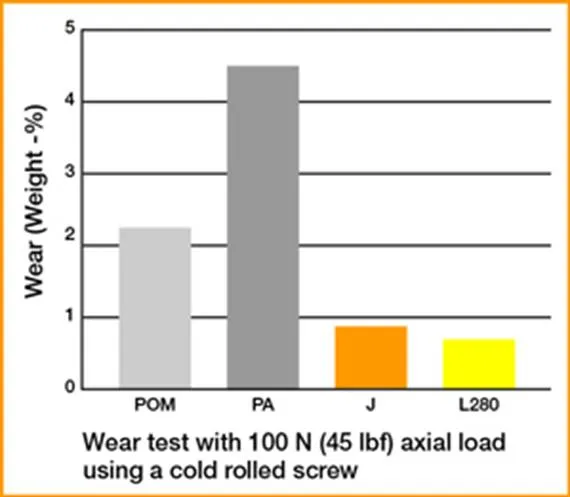

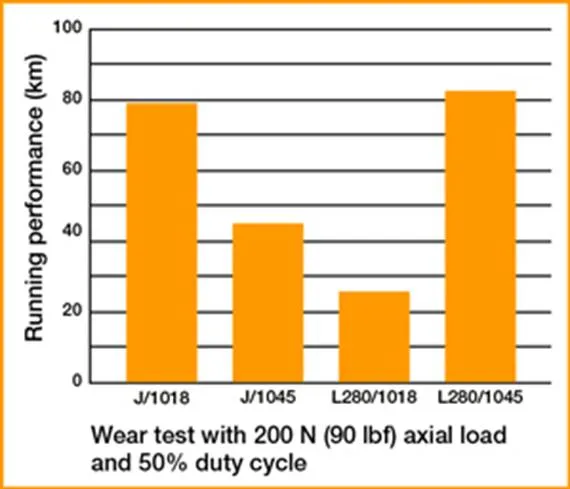

Traditional materials for lead screw nuts are typically brass, oil-impregnated bronze, and simple plastic materials. igus® tribo-plastics, such as iglide® J and iglide® L280 are composite plastic materials, which offer lower friction and wear values than many other materials across a whole range of applications. These composites operate free of any oil and grease, and do not require maintenance. They are able to operate on traditional ferrous lead screws, as well as low-weight aluminum lead screws.

|

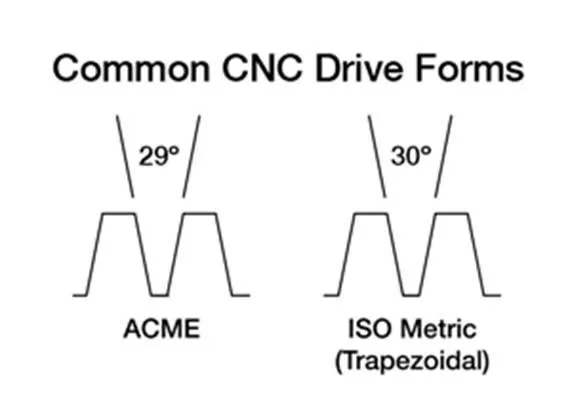

The single-start ACME thread is the most common form of the lead screw nut in North America. Developed in the mid-1800s, they can be found on all types of machines, and are most suited to low-cycle or positioning applications. Their trapezoidal shape makes them better suited for the axial loading found in power transmission applications.

Standards for single-start ACME nuts apply to the inner thread dimensions. ACME lead screws are called out by their diameter, and then the threads-per-inch (TPI). For example:

A ¾-20 ACME has a major ID of 0.75” and 20 TPI

To calculate the lead (linear travel in inches per one screw revolution) simply divide 1 inch by the TPI. In the above example a 20-TPI nut will travel 0.05” per one revolution.

|

Trapezoidal lead screws, sometimes referred to as “metric ACME”, are almost identical to ACME lead screw forms, and are more commonplace in Europe and Asia. The major difference from regular ACME is that they are based on metric dimensions, and the angle differs by 1°.

Trapezoidal screws are generally covered by ISO standards for inner and outer geometry. Unlike ACME, they are specified by their major inner-diameter (in mm), and then their pitch (in mm). For example, a trapezoidal 10mm ID screw with a 2mm pitch is called out by: TR 10 x 2

It is important to note that we have been discussing single-start screws. This means that there is one continuous thread on the individual screw. Many manufacturers offer multi-start ACME screws, but the geometries are not necessarily compatible from one manufacturer to another. Multiple-start lead screws benefit from higher load capabilities compared to single-start screws. However, they lose their mechanical advantage, meaning they require higher input torque than single-start screws.