Types of Cores

Cores are generally made of green sand or dry sand. The green sand cores have relatively low strength being made of green sand, whereas dry sand cores are made of sand and special binders which develop strength when baked.

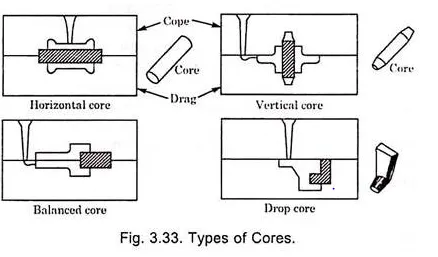

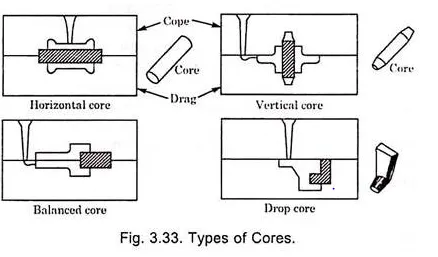

These could also be classified according to their position or use, according to which these can be of horizontal, vertical, balanced, drop and other types. These four types will be clear from Fig. 3.33.

Horizontal and vertical cores are used more frequently than other types. In the case of balanced core, the core print should be sufficiently large to support the weight of core, which extends into mould cavity from one side only. It should be able to withstand the force of buoyancy of the molten metal surrounding it.

Making of Cores:

Cores are made separately in a core box made of wood or metal. The various steps in core making are ramming of core sand in the box, venting, reinforcing, removing of core from box, baking, pasting, sizing etc. This work of producing cores can either be done by hand or by some machines designed for this purpose.

In machine moulding, the core sand mixture is rammed by jolting, squeezing or blowing by means of suitable machine. Venting, reinforcing and other operations are carried out by hand. Cores of symmetrical cross-section can be produced by extruding core sand mixture through a suitable die opening. The cores by extrusion process are made in lengths and cut to shorter length as needed.

Cores are generally made by core blowing machine for production work, in which the core sand is placed in small hopper over the clamped core box and blown under a pressure of 5 to 8 kgf/cm2. The core boxes are of special construction to provide for escapement of air. It requires special drying equipment. Even complex cores can be produced in a few seconds by core blowing method.

Core boxes used for core-making are designed in several types which aid in core removal. The most commonly used are of split, rollover and hooked type.

Baking of Cores:

Generally baking is carried out in ovens equipped with drawers, shelves or other holding devices. The operation is generally continuous and cores are put either in batches or continuously over moving shelves. The heat in oven is produced by burning oil or coke or by electric resistance.

Core-baking time depends upon the type and quantity of binder used, the amount of moisture used in sand, and size of core. The temperature for baking depends on the core material used. When cores are baked, they are more easily supported on a flat surface, which should be incorporated in the design.

Dressing of Cores:

Dressing of cores is the operation of applying a compound to the surface of a core, either in the green state or after baking, for the purpose of providing protection against the scouring action of flowing molten metal and to assist the formation of a smooth surface in a cored hole or cored form.

Core Chaplet:

A core chaplet is a metal location piece inserted in a mould either to prevent a core shifting its position or to give extra support to a core. The molten metal melts the chaplet, which then forms part of the cast material.

Method of Supporting Cores in the Mould:

Generally core prints are provided in cores. These core prints are a sort of projection at the end of core and these support the core in position in a mould. Design should provide space for core prints sufficiently large to locate the core accurately, prevent sagging, and resist the hydrostatic molten-metal pressure.

In some cores, small metal props (chaplets) are also used which are placed in the mould cavity to support the core and these props fuse and become part of casting. The chaplets, therefore, must be clean, dry and selected of proper material.

Sometimes small metal insert hinge tubes are also used to provide support for tiny hole-forming cores. As far as possible chaplets should be avoided as fusing is not always easily accomplished, and it may lead to production of unsound castings.

Some cores are nearly fully surrounded by metal, and a vent then becomes necessary to release the gases generated during pouring. If possible, the hole formed by the vent core should be incorporated as functional part of the design or located where it will do no harm, otherwise welding or plugging would be required.