3 Main Types of Moulding Machines

This article throws light upon the three main types of moulding machines. The types are: 1. Squeezers 2. Jolt Machines 3. Sand Slingers.

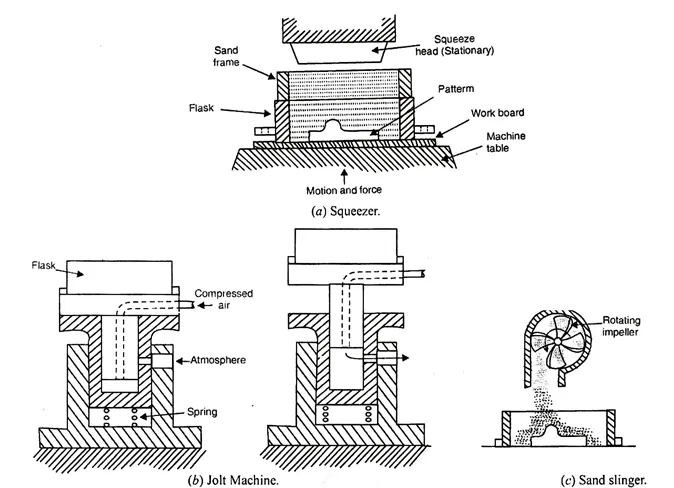

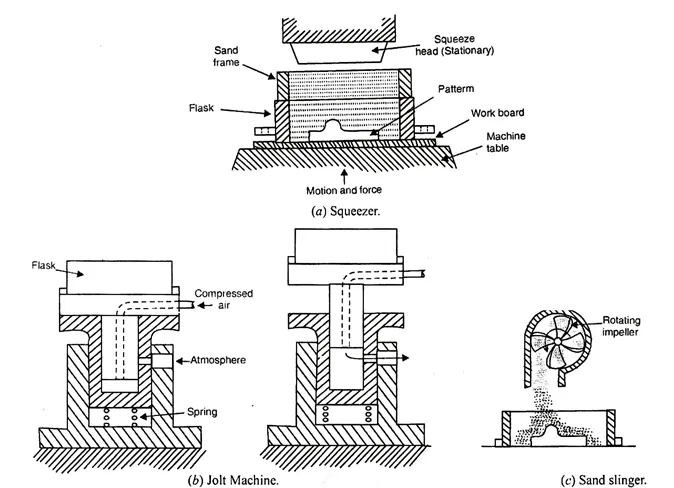

The working principle of a squeezer type moulding machine is shown in Fig. 4.11 (a). The pattern plate is clamped on the machine table, and a flask is put into position. A sand frame is placed on the flask, and both are then filled with sand from a hopper.

Next, the machine table travels upward to squeeze the sand between the pattern plate and a stationary squeeze head. The squeeze head enters into the sand frame and compacts the sand so that it is level with the edge of the flask. These machines rammed the sand harder at the back of the mould and softer on the pattern face. Squeezer machines are very useful for shallow patterns.

The working principle of jolt type of moulding machine is shown in Fig. 4.11 (b). As can be seen, compressed air admitted through the hose to a pressure cylinder to lift the plunger and the flask, which is full of sand, up to a certain height, where the side hole is uncovered to exhaust the compressed air.

The plunger then falls down and strikes the stationary guiding cylinder. The shock waves generating from each of successive impacts contributes to packing or ramming the moulding sand in the flask.

The working principle of a sand slinger machine is shown in Fig. 4.11 (c). As can be seen, moulding sand is fed into a housing containing an impeller that rotates rapidly around a horizontal axis.

Sand particles are picked up by the rotating blades and thrown at a high speed through an opening onto the pattern, which is positioned in the flask. This type of machine is employed in moulding sand in flasks of any size, whether for mass production of moulds or individual mould.

There are also some machines, such as jolt-squeeze machines, that employ a combination of the working principles of two of the main types. No matter what type of moulding machine is used, special machines are used to draw the pattern out of the mould.

Basically, these machines achieve this by turning the flask (together with the pattern) upside, down and then lifting the pattern out of the mould. Roll-over moulding machines and rock-over pattern-draw machines, are some examples of this category.

Figure:4.11 .molding machines