Powder Bed Fusion

The Powder Bed Fusion process includes the following commonly used printing techniques: Direct metal laser sintering (DMLS), Electron beam melting (EBM), Selective heat sintering (SHS), Selective laser melting (SLM) and Selective laser sintering (SLS).

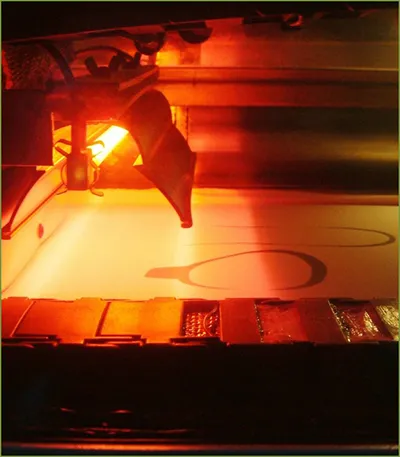

Powder bed fusion (PBF) methods use either a laser or electron beam to melt and fuse material powder together. Electron beam melting (EBM), methods require a vacuum but can be used with metals and alloys in the creation of functional parts. All PBF processes involve the spreading of the powder material over previous layers. There are different mechanisms to enable this, including a roller or a blade. A hopper or a reservoir below of aside the bed provides fresh material supply. Direct metal laser sintering (DMLS) is the same as SLS, but with the use of metals and not plastics. The process sinters the powder, layer by layer. Selective Heat Sintering differs from other processes by way of using a heated thermal print head to fuse powder material together. As before, layers are added with a roller in between fusion of layers. A platform lowers the model accordingly.

Powder Bed Fusion – Step by Step

1. A layer, typically 0.1mm thick of material is spread over the build platform.

2. A laser fuses the first layer or first cross section of the model.

3. A new layer of powder is spread across the previous layer using a roller.

4. Further layers or cross sections are fused and added.

5. The process repeats until the entire model is created. Loose, unfused powder is remains in position but is removed during post processing.