SLA vs. FDM

In FDM, filament is fed through a hot extruder and deposited layer-by-layer. The materials used are typically thermoplastics, but they can be mixed with other elements, including wood, metal, and carbon fiber. This is one advantage over SLA, which has only a limited choice of materials.

Whereas in FDM resolution refers to the precision of the motors, in SLA it depends on the tightness of the laser beam. This is why SLA is capable of producing objects of higher detail and accuracy.

An object printed using an FDM 3D printer is post-processed by removing supports (if present) and smoothening surfaces. In SLA, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive UV light for extra strengthening. Nevertheless, the final result is in general not as strong as a product of FDM.

The cost of materials is decisively lower for FDM, since the printers are more affordable, and plastic reels are cheaper than resin.

In a nutshell, if high precision and a smooth finish are priorities, SLA will be your best bet. If cost and (to a lesser extent) durability play a role, use an FDM printer. For a more in-depth comparison, take a look at our article FDM vs SLA: The Differences – Simply Explained.

SLA vs. SLS

Selective laser sintering (SLS) involves an entirely different approach, although it also involves the use of a laser

Although it also uses a laser, it’s much more powerful. That’s because, instead of curing a substance, the beam heats a powder to the point of fusing its particles together. Often grouped with SLS are direct metal laser sintering (DMLS) and selective laser melting (SLM), which are specifically adapted to metals. Normal SLS works with polymers like nylon.

Compared to objects made with other technologies, SLS prints are especially strong and durable. Also, because supports aren’t necessary in SLS, prints can be of complex geometries. Detailing can be fairly high with SLS, it generally can’t compare to the precision of SLA.

Because of their highly powered lasers, SLS machines incorporate more advanced technology, including special shielding against harmful UV radiation. This results in printers that are more expensive, with few desktop or benchtop options available.

Furthermore, SLS powders are more expensive than liquid photopolymers.

In a nutshell, if high mechanical strength and complex shapes are your priority, and the cost is of minor importance, use an SLS printer. Otherwise, SLA is probably your best bet. For a more in-depth comparison, check out our article SLA vs SLS: The Differences – Simply Explained.

Final Remarks

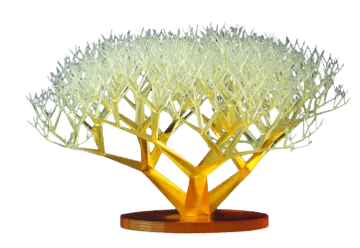

An example of a fractal tree, a complex geometry printable using stereolithography.

Although stereolithography is the first process developed for rapid prototyping, and the oldest among the main 3D printing methods, it still remains an attractive solution for creating prototypes with high accuracy and durability. Many industries and hobbyists use this process to build prototypes as well as final products, and the technology continues to become more affordable and accessible.