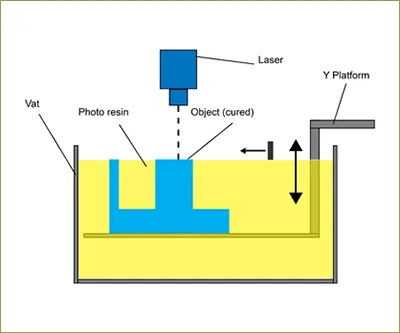

VAT Photopolymerisation

Vat polymerisation uses a vat of liquid photopolymer resin, out of which the model is constructed layer by layer. An ultraviolet (UV) light is used to cure or harden the resin where required, whilst a platform moves the object being made downwards after each new layer is cured.

As the process uses liquid to form objects, there is no structural support from the material during the build phase., unlike powder based methods, where support is given from the unbound material. In this case, support structures will often need to be added. Resins are cured using a process of photo polymerisation (Gibson et al., 2010) or UV light, where the light is directed across the surface of the resin with the use of motor controlled mirrors (Grenda, 2009). Where the resin comes in contact with the light, it cures or hardens.

Photopolymerisation – Step by Step

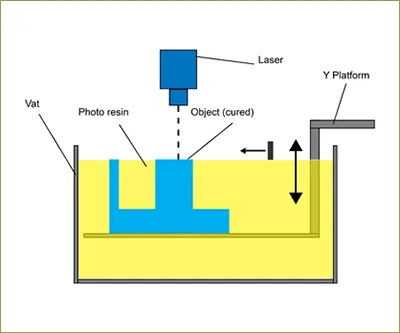

1. The build platform is lowered from the top of the resin vat downwards by the layer thickness.

2. A UV light cures the resin layer by layer. The platform continues to move downwards and additional layers are built on top of the previous.

3. Some machines use a blade which moves between layers in order to provide a smooth resin base to build the next layer on.

4. After completion, the vat is drained of resin and the object removed.