How can you identify parts for consolidation?

When thinking about part consolidation with AM, the first step is to focus on the function of the assembly that you plan on replacing. Then you need to question the assumptions that led to your original design made using traditional manufacturing.

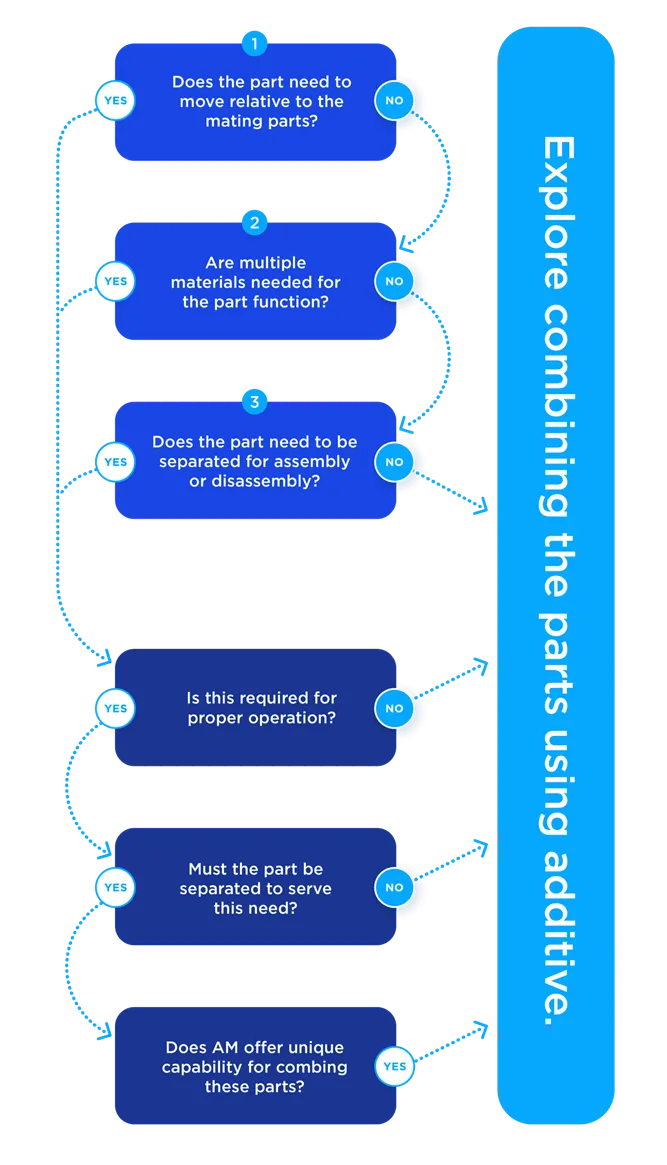

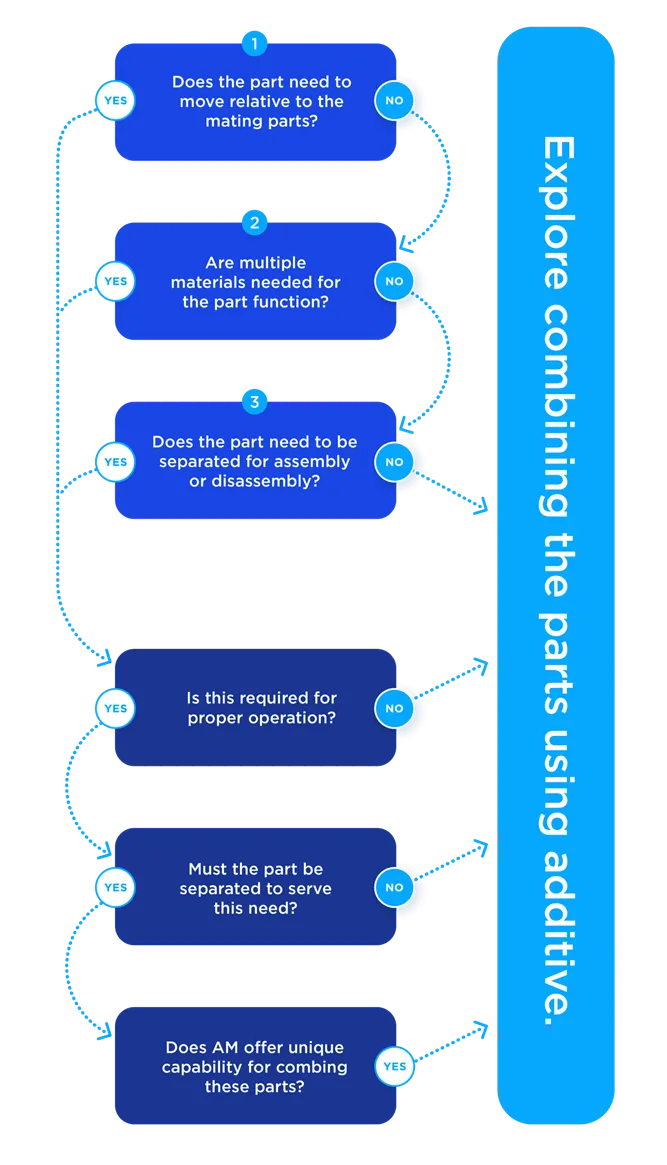

It can be helpful to use a structured approach to analyzing the parts to be consolidated. An effective and popular methodology for analyzing manufacturing and assembly is known as Design for Manufacture and Assembly (DFMA®). The model is made up of three questions that help engineers and manufacturers begin the assembly consolidation process:

1. Does the part need to move relative to the parts assembled?

2. Are multiple materials needed for the part function?

3. Does the part need to be separated for assembly or disassembly?

By thinking through these questions, designers can determine the theoretical minimum number of parts required for assembly. While these questions can serve as a starting point, there are a few follow up considerations that will help you determine if you should be thinking of additive for part consolidation:

1. Are multiple parts needed to satisfy this requirement?

2. Can a single part satisfy this requirement?

In other words, are multiple parts truly needed for the part to function properly? Are there other solutions, such as lattice structures (or other complex geometries), that could be incorporated into a design that could essentially serve the same function while reducing the amount of parts and materials required overall?

Take a look at the chart below to help determine if part consolidation using additive is right for you.

Part consolidation and additive processes

Designing to reduce the number of separate components is only one factor in part consolidation. Another way to minimize the number of assembled parts in your product is to use technologies that make consolidation possible. With additive technologies, such as HP Multi Jet Fusion (MJF), separate components have the ability to not only be printed as one whole piece, but are capable of a full range of motion straight off the printer.

Deciding on which additive technology to use depends on your design requirements. For example, with HP MJF, parts do not require supports, which enabled engineers to create more complex designs and movable pieces. Carbon® technology does require supports, but is able to print durable components with varying wall thicknesses as one piece. A great example of part consolidation using Carbon® is the Steelcase’s SILQ chair armrest: the armrest used to be assembled using three separate pieces, but thanks to lattice structures and complex geometries, is now printed as one.

Part consolidation application examples

There are many applications that could benefit from part consolidation using AM. There are already applications on the market, such as mechanical assemblies, fluidic components, structural pieces, and more. Manufacturers are seeing increased performance and durability thanks to designing multiple parts as one. Let’s take a closer look at how part consolidation impacts two specific applications.

Pump impellers

Traditionally-manufactured impellers often require separate parts that are welded together. With AM, these can be printed as one single piece. When a pump impeller is traditionally manufactured, it will have gaps between its components. By manufacturing with additive, the gap can be removed – which improves the part’s overall performance. It’s also important to note that because the welded joints have been eliminated, the number of potential failure points have been reduced and corrosion at the welds will no longer occur.

Air ducting

Air ducts are also great candidates for part consolidation. Using complex geometries enabled by additive, the part geometry and air flow can be optimized. A case example of this is a cooling duct in the HP 500/300 printer series that utilizes HP MJF. By consolidating eight parts into one, HP was able to simplify their supply chain and lower the component cost by 30 percent.

Manufacturers strive to achieve the reduction cost, supply chain risk, and improved performance through part consolidation. AM offers a unique opportunity to further reduce assemblies due to the complex geometries that are now possible. If you want to learn more about how your application can be consolidated, contact our team of experts today