Lathe Operations

For performing the various machining operations in a lathe, the job is being supported and driven by anyone of the following methods.

1. Job is held and driven by chuck with the other end supported on the tail stock centre.

2. Job is held between centers and driven by carriers and catch plates.

3. Job is held on a mandrel, which is supported between centers and driven by carriers and catch plates.

4. Job is held and driven by a chuck or a faceplate or an angle plate.

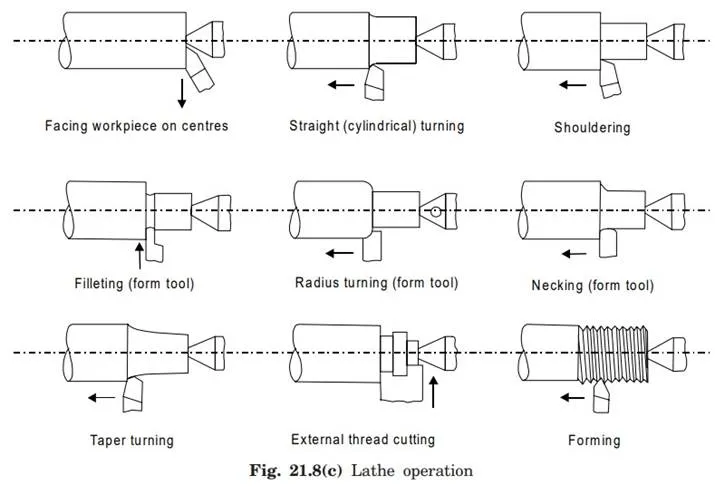

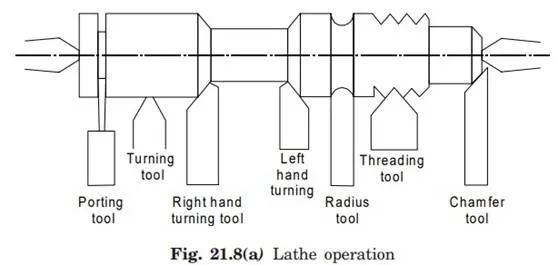

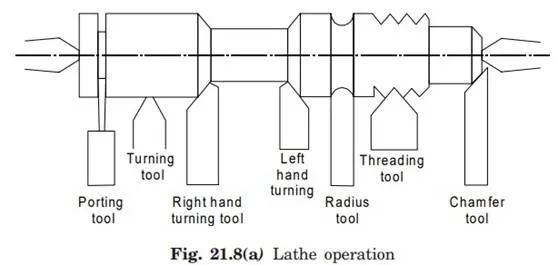

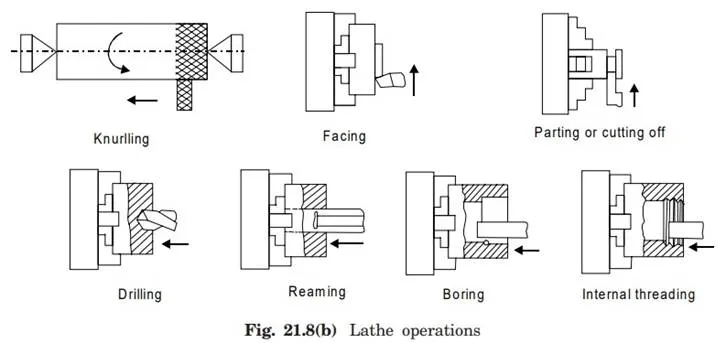

The above methods for holding the job can be classified under two headings namely job held between centers and job held by a chuck or any other fixture. The various important lathe operations are depicted through Fig. 21.8 (a), (b) and (c). The operations performed in a lathe can be understood by three major categories.

a) Operations, which can be performed in a lathe either by holding the workpiece between centers or by a chuck are:

1. Straight turning

2. Shoulder turning

3. Taper turning

4. Chamfering

5. Eccentric turning

6. Thread cutting

7. Facing

8. Forming

9. Filing

10. Polishing

11. Grooving

12. Knurling

13. Spinning

14. Spring winding

(b) Operations which are performed by holding the work by a chuck or a faceplate or an angle plate are:

1. Undercutting

2. Parting-off

3. Internal thread cutting

4. Drilling

5. Reaming

6. Boring

7. Counter boring

8. Taper boring

9. Tapping

(c) Operations which are performed by using special lathe attachments are:

1. Milling

2. Grinding