METAL CUTTING

Metal cutting or traditional machining processes are also known as conventional machining processes. These processes are commonly carried out in machine shops or tool room for machining a cylindrical or flat jobs to a desired shape, size and finish on a rough block of job material with the help of a wedge shaped tool. The cutting tool is constrained to move relative to the job in such a way that a layer of metal is removed in the form of a chip. General metal cutting operations are shown in Fig. 20.1. These machining processes are performed on metal cutting machines, more commonly termed as machine tools using various types of cutting tools (single or multi-point). A machine tool is a power driven metal cutting machine which assist in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. In metal cutting (machining) process, working motion is imparted to the workpiece and cutting tool by the mechanisms of machine tool so that the work and tool travel relative to each other and machine the workpiece material in the form of shavings (or swarf) known as chips.

The machine tools involve various kinds of machines tools commonly named as lathe, shaper, planer, slotter, drilling, milling and grinding machines etc. The machining jobs are mainly of two types namely cylindrical and flats or prismatic. Cylindrical jobs are generally machined using lathe, milling, drilling and cylindrical grinding whereas prismatic jobs are machined using shaper, planner, milling, drilling and surface grinding.

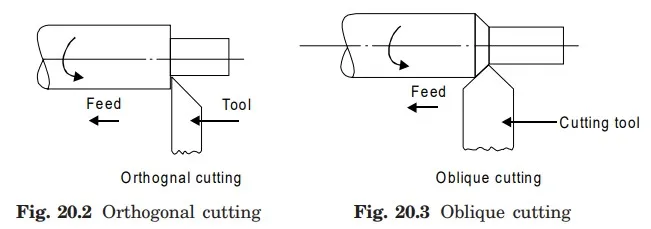

In metal cutting operation, the position of cutting edge of the cutting tool is important based on which the cutting operation is classified as orthogonal cutting and oblique cutting. Orthogonal cutting (Fig. 20.2) is also known as two dimensional metal cutting in which the cutting edge is normal to the work piece. In orthogonal cutting no force exists in direction perpendicular to relative motion between tool and work piece. Oblique cutting (Fig. 20.3) is the common type of three dimensional cutting used in various metal cutting operations in which the cutting action is inclined with the job by a certain angle called the inclination angle.