Metal Flow in Deep Drawing

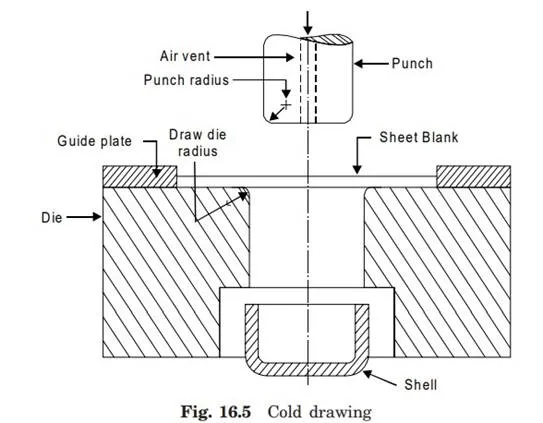

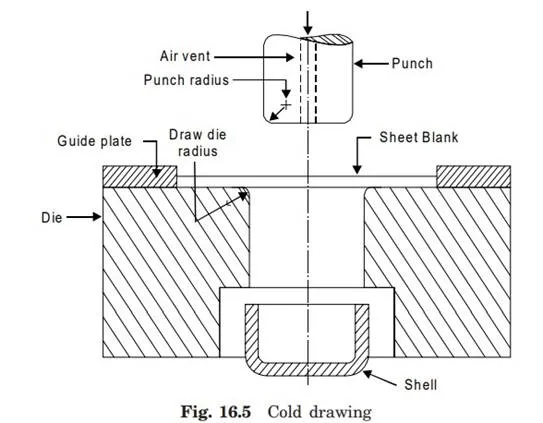

Dies When the punch of a deep drawing press forces a portion of metal blank through the bore of the drawing, different forces came into action to cause a rather complicated plastic flow of the material. The volume and thickness of the metal remain essentially constant, and the final shape of the cup will be similar to the contour of the punch. The flow of metal is summarized as follows.

(i) There is no metal deformation takes place in the blank area which forms the bottom of the cup.

(ii) The metal flow of the volume elements at the periphery of the blank is extensive and involves an increase in metal thickness caused by severe circumferential compression. The increase is usually slight because it is restricted by the clearance between the punch and bore wall of the die ring.

(iii) The metal flow taking place during the forming of the cup will uniformly increases with cup height.