SHELL MOLD CASTING

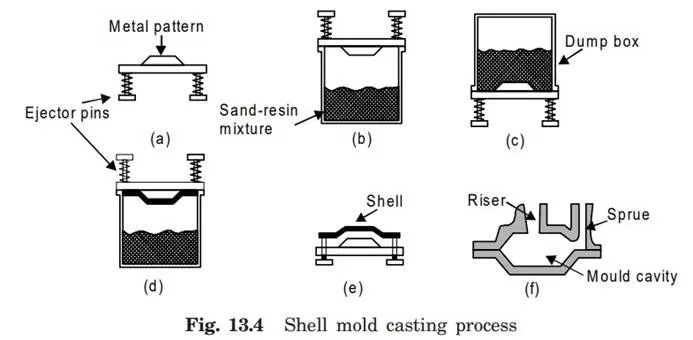

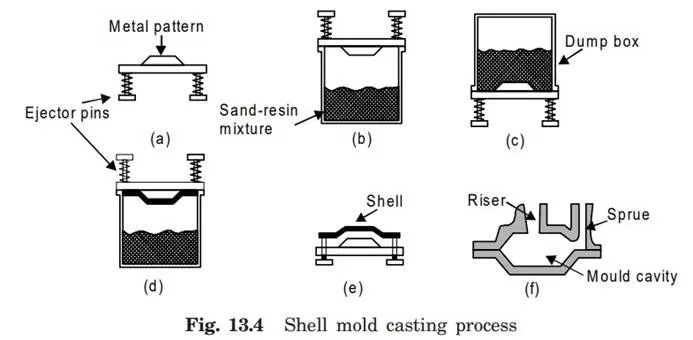

Shell mold casting process is recent invention in casting techniques for mass production and smooth surface finish. It was originated in Germany during Second World War. It is also called as Carning or C process. It consists of making a mold that possesses two or more thin shells (shell line parts, which are moderately hard and smooth with a texture consisting of thermosetting resin bonded sands. The shells are 0.3 to 0.6 mm thick and can be handled and stored. Shell molds are made so that machining parts fit together-easily. They are held using clamps or adhesive and metal is poured either in a vertical or horizontal position. They are supported using rocks or mass of bulky permeable material. Thermosetting resin, dry powder and sand are mixed thoroughly in a muller. Complete shell molding casting processes is carried in four stages as shown in Fig. 13.4. In this process a pattern is placed on a metal plate and it is then coated with a mixture of fine sand and Phenol-resin (20:1). The pattern is heated first and silicon grease is then sprayed on the heated metal pattern for easy separation. The pattern is heated to 205 to 230°C and covered with resin bounded sand. After 30 seconds, a hard layer of sand is formed over pattern. Pattern and shell are heated and treated in an oven at 315°C for 60 secs.,

Phenol resin is allowed to set to a specific thickness. So the layer of about 4 to 10 mm in thickness is stuck on the pattern and the loose material is then removed from the pattern. Then shell is ready to strip from the pattern. A plate pattern is made in two or more pieces and similarly core is made by same technique. The shells are clamped and usually embedded in gravel, coarse sand or metal shot. Then mold is ready for pouring. The shell so formed has the shape of pattern formed of cavity or projection in the shell. In case of unsymmetrical shapes, two patterns are prepared so that two shell are produced which are joined to form proper cavity. Internal cavity can be formed by placing a core. Hot pattern and box is containing a mixture of sand and resin. Pattern and box inverted and kept in this position for some time. Now box and pattern are brought to original position. A shell of resin-bonded sand sticks to the pattern and the rest falls. Shell separates from the pattern with the help of ejector pins. It is a suitable process for casting thin walled articles. The cast shapes are uniform and their dimensions are within close limit of tolerance ± 0.002 mm and it is suitable for precise duplication of exact parts. It has various advantages which are as follows. There are some advantages and disadvantages of this process which are given as under.

Advantages

The main advantages of shell molding are:

(i) Very suitable for thin sections like petrol engine cylinder.

(ii) Excellent surface finish.

(iii) Good dimensional accuracy of order of 0.002 to 0.003 mm.

(iv) Negligible machining and cleaning cost.

(v) Occupies less floor space.

(vi) Skill-ness required is less.

(vii) Molds can be stored until required.

(viii) Better quality of casting assured.

(ix) Mass production.

Disadvantages

(i) Initial cost is high.

(ii) Specialized equipment is required.

(iii) Resin binder is an expensive material.

(iv) Limited for small size.

(v) Future of shell molding process is very bright.

Applications

(i) Suitable for production of casting made up of alloys of Al, Cu and ferrous metals

(ii) Bushing

(iii) Valves bodies

(iv) Rocker arms

(v) Bearing caps

(vi) Brackets

(vii) Gears