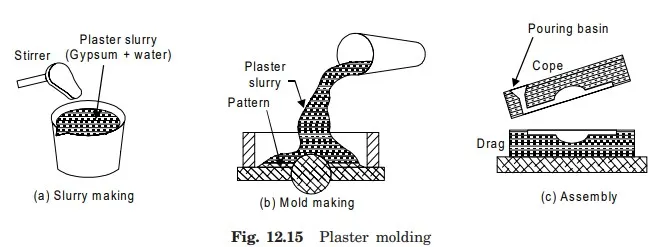

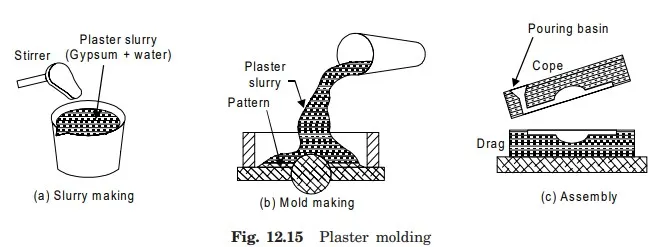

Plaster Molding

Plaster molding process is depicted through Fig. 12.15. The mould material in plaster molding is gypsum or plaster of paris. To this plaster of paris, additives like talc, fibers, asbestos, silica flour etc. are added in order to control the contraction characteristics of the mould as well as the settling time. The plaster of paris is used in the form of a slurry which is made to a consistency of 130 to 180. The consistency of the slurry is defined as the pounds of water per 100 pounds of plaster mixture. This plaster slurry is poured over a metallic pattern confined in a flask. The pattern is usually made of brass and it is generally in the form of half portion of job to be cast and is attached firmly on a match plate which forms the bottom of the molding flask. Wood pattern are not used because the water in the plaster raises the grains on them and makes them difficult to be withdrawn. Some parting or release agent is needed for easy withdrawal of the pattern from the mold. As the flask is filled with the slurry, it is vibrated so as to bubble out any air entrapped in the slurry and to ensure that the mould is completely filled up. The plaster material is allowed to set. Finally when the plaster is set properly the pattern is then withdrawn by separating the same, from the plaster by blowing compressed air through the holes in the patterns leading to the parting surface between the pattern and the plaster mold. The plaster mold thus produced is dried in an oven to a temperature range between 200-700 degree centigrade and cooled in the oven itself. In the above manner two halves of a mould are prepared and are joined together to form the proper cavity. The necessary sprue, runner etc. are cut before joining the two parts.

Advantages

(a) In plaster molding, very good surface finish is obtained and machining cost is also reduced.

(b) Slow and uniform rate of cooling of the casting is achieved because of low thermal conductivity of plaster and possibility of stress concentration is reduced.

(c) Metal shrinkage with accurate control is feasible and thereby warping and distortion of thin sections can be avoided in the plaster molding.

Limitations

(a) There is evolution of steam during metal pouring if the plaster mold is not dried at higher temperatures avoid this, the plaster mold may be dehydrated at high temperatures, but the strength of the mould decreases with dehydration.

(b) The permeability of the plaster mold is low. This may be to a certain extent but it can be increased by removing the bubbles as the plaster slurry is mixed in a mechanical mixer.