Carbon-Dioxide Gas Molding

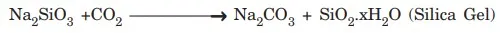

This process was widely used in Europe for rapid hardening the molds and cores made up of green sand. The mold making process is similar to conventional molding procedure accept the mould material which comprises of pure dry silica sand free from clay, 3-5% sodium silicate as binder and moisture content generally less than 3%. A small amount of starch may be added to improve the green compression strength and a very small quantity of coal dust, sea coal, dextrin, wood floor, pitch, graphite and sugar can also be added to improve the collapsibility of the molding sand. Kaolin clay is added to promote mold stability. The prepared molding sand is rammed around the pattern in the mould box and mould is prepared by any conventional technique. After packing, carbon dioxide gas at about 1.3-1.5 kg/cm2 pressure is then forced all round the mold surface to about 20 to 30 seconds using CO2 head or probe or curtain as shown in Fig. 12.14. The special pattern can also be used to force the carbon dioxide gas all round the mold surfaces. Cores can be baked this way. The sodium silicate presented in the mold reacts with CO2 and produce a very hard constituents or substance commonly called as silica gel.

This hard substance is like cement and helps in binding the sand grains. Molds and cores thus prepared can be used for pouring molten metal for production of both ferrous and nonferrous casting. The operation is quick, simple require semi-skilled worker. The evolution of gases is drastically reduced after pouring the thus prepared mould. This process eliminates mold and core baking oven. Reclamation of used sand is difficult for this process.