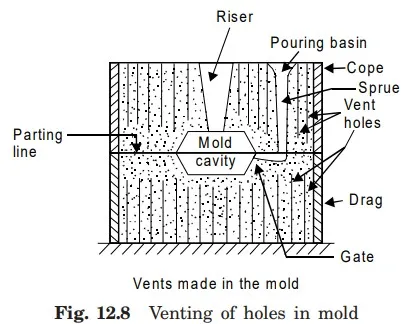

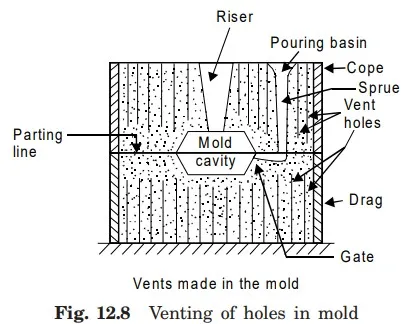

VENTING OF MOLDS

Vents are very small pin types holes made in the cope portion of the mold using pointed edge of the vent wire all around the mold surface as shown in Fig. 12.8. These holes should reach just near the pattern and hence mold cavity on withdrawal of pattern. The basic purpose of vent holes is to permit the escape of gases generated in the mold cavity when the molten metal is poured. Mold gases generate because of evaporation of free water or steam formation, evolution of combined water (steam formation), decomposition of organic materials such as binders and additives (generation of hydrocarbons, CO and CO2), expansion of air present in the pore spaces of rammed sand. If mold gases are not permitted to escape, they may get trapped in the metal and produce defective castings. They may raise back pressure and resist the inflow of molten metal. They may burst the mold. It is better to make many small vent holes rather than a few large ones to reduce the casting defects.