Core And Core Box

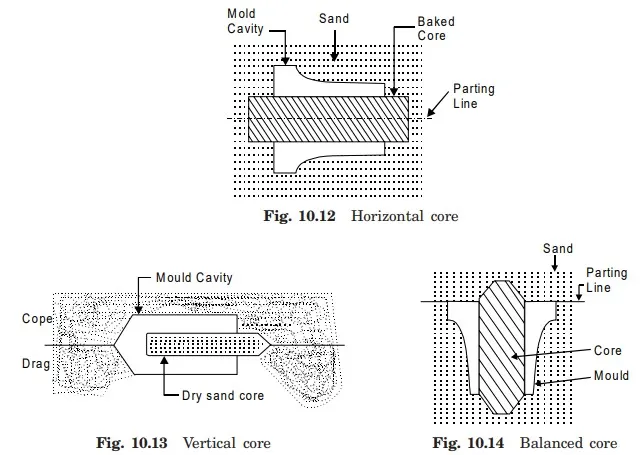

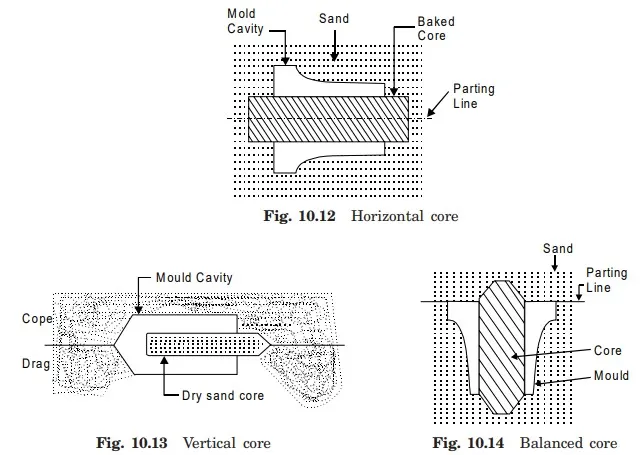

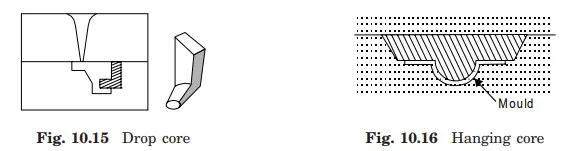

Cores are compact mass of core sand that when placed in mould cavity at required location with proper alignment does not allow the molten metal to occupy space for solidification in that portion and hence help to produce hollowness in the casting. The environment in which the core is placed is much different from that of the mold. In fact the core (Fig. 10.12) has to withstand the severe action of hot metal which completely surrounds it. Cores are classified according to shape and position in the mold. There are various types of cores such as horizontal core (Fig. 10.13), vertical core (Fig. 10.14), balanced core (Fig. 10.15), drop core (Fig. 10.16) and hanging core (Fig. 10.17).

There are various functions of cores which are given below

1. Core is used to produce hollowness in castings in form of internal cavities.

2. It may form a part of green sand mold.

3. It may be deployed to improve mold surface.

4. It may provide external under cut features in casting.

5. It may be used to strengthen the mold.

6. It may be used to form gating system of large size mold

7. It may be inserted to achieve deep recesses in the casting