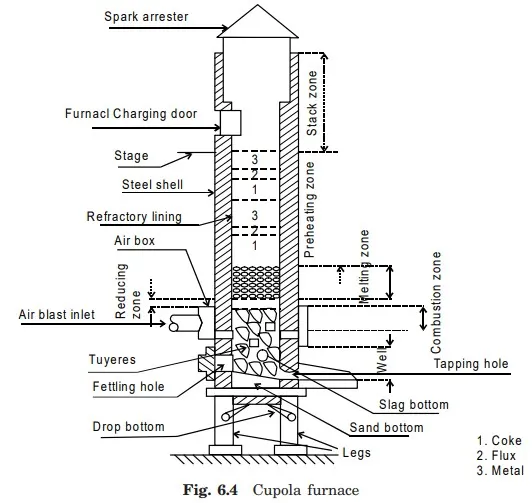

CUPOLA FURNACE

Cupola furnace is employed for melting scrap metal or pig iron for production of various cast irons. It is also used for production of nodular and malleable cast iron. It is available in good varying sizes. Fig. 6.4 shows the various parts and zones of cupola furnace. The main considerations in selection of cupolas are melting capacity, diameter of shell without lining or with lining, spark arrester.

Various Zones of Cupola Furnace

Various numbers of chemical reactions take place in different zones of cupola. The construction and different zones of cupola are discussed as under.

1. Well

The space between the bottom of the tuyeres and the sand bed inside the cylindrical shell of the cupola is called as well of the cupola. As the melting occurs, the molten metal is get collected in this portion before tapping out.

2. Combustion zone

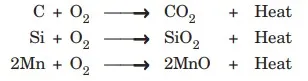

The combustion zone of Cupola is also called as oxidizing zone. It is located between the upper of the tuyeres and a theoretical level above it. The total height of this zone is normally from 15 cm. to 30 cm. The combustion actually takes place in this zone by consuming the free oxygen completely from the air blast and generating tremendous heat. The heat generated in this zone is sufficient enough to meet the requirements of other zones of cupola. The heat is further evolved also due to oxidation of silicon and manganese. A temperature of about 1540°C to 1870°C is achieved in this zone. Few exothermic reactions takes place in this zone these are represented as :

3. Reducing zone

Reducing zone of Cupola is also known as the protective zone which is located between the upper level of the combustion zone and the upper level of the coke bed. In this zone, CO2 is changed to CO through an endothermic reaction, as a result of which the temperature falls from combustion zone temperature to about 1200°C at the top of this zone. The important chemical reaction takes place in this zone which is given as under.

Nitrogen does not participate in the chemical reaction occurring in his zone as it is also the other main constituent of the upward moving hot gases. Because of the reducing atmosphere in this zone, the charge is protected against oxidation.

4. Melting zone

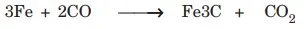

The lower layer of metal charge above the lower layer of coke bed is termed as melting zone of Cupola. The metal charge starts melting in this zone and trickles down through coke bed and gets collected in the well. Sufficient carbon content picked by the molten metal in this zone is represented by the chemical reaction given as under.

5. Preheating zone

Preheating zone starts from the upper end of the melting zone and continues up to the bottom level of the charging door. This zone contains a number of alternate layers of coke bed, flux and metal charge. The main objective of this zone is to preheat the charges from room temperature to about 1090°C before entering the metal charge to the melting zone. The preheating takes place in this zone due to the upward movement of hot gases. During the preheating process, the metal charge in solid form picks up some sulphur content in this zone.

6. Stack

The empty portion of cupola above the preheating zone is called as stack. It provides the passage to hot gases to go to atmosphere from the cupola furnace.

Charging of Cupola

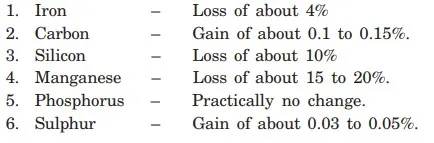

Furnace Before the blower is started, the furnace is uniformly pre-heated and the metal and coke charges, lying in alternate layers, are sufficiently heated up. The cover plates are positioned suitably and the blower is started. The molten metal starts trickling down and collecting in the well. The height of coke charge in the cupola in each layer varies generally from 10 to 15 cms. The requirement of flux to the metal charge depends upon the quality of the charged metal and scarp, the composition of the coke and the amount of ash content present in the coke. Generally about 40 kg to 50 kg of limestone, in form of flux, per metric ton of the metal is used. The amount of this flux to be charged should be properly determined. The excess amount of flux affects the acid lining of cupola. Lesser amount of the flux than required will result in the loss of molten metal. First charge received of the molten metal is either allowed to drain out or used for rough castings. For having desired composition of the casting, it is essential to control the proportions of its various constituents at the stage of raw material requirement for melting. It is also necessary due to number of losses and gains of different constituents take place inside the cupola during the process of melting. These losses and gains in composition are identified for compensating purposes. The losses or gains of different constituents during melting as identified are given as under:

Working of Cupola Furnace

Initially the furnace prop is opened to drop the existing earlier charge residue. The furnace is then repaired using rich refractory lining. After setting the prop in position, the fire is ignited using firewood and then small amount of coke is used to pick fire. The little oxygen is then supplied for combustion. Lime, coke, and metal in balanced proportions are charged through the charging door upon the coke bed and at proper time on starting the blower. Air is forced from wind box through tuyers into furnace. The forced air rise upward rough the stack furnaces for combustion of coke. Besides being fuel, the coke supports the charge until melting occurs. On increase of temperature, the lime stone melts and forms a flux which protects the metal against from excessive oxidation. Lime also fuses and agglomerates the coke ash. The melting occurs and proceeds and molten metal is collected at the bottom. Molten metal may be tapped at intervals before each skimming, or the tap-hole may be left open with metal flowing constantly. In most cupolas slag is drained from the slag hole at the back of furnace. When metal is melted completely the bottom bar is pulled sharply under the plates and bottom is dropped. All remaining slag, un-burned coke or molten metal drops from the furnace. When the melt charge has cooled on closing furnace, it is patched and made ready for the next heat.

Applications of Cupola

Cupola is most widely used for melting practices for production of grey cast iron, nodular cast iron, malleable cast iron and alloy cast iron. It can be used for melting some copper-base alloys, and in duplexing and triplexing operations for making of steel, malleable cast iron and ductile cast iron. Steel can be also prepared in cupola by employing duplexing and triplexing operations. In duplexing melting operation two furnaces are used, and triplexing operations, three furnaces are employed.

Jamming of Cupola Furnace

Jamming of cupola furnace is a very common problem for which sufficient care should be taken to prevent it. It occurs frequently due to the negligence of the furnace operator. The cupola furnace may be either jammed temporarily or permanently and the same are discussed as under.

Temporary Jamming of Cupola Furnace

Temporary jamming of cupola furnace means the temporary suspension of air supply in the tuyere zone due to choking of the tuyere mouths. This is caused mainly due to the low temperatures at the tuyere openings resulting in the solidification of iron and slag around these openings. The air passage is hence chocked and the supply of air is temporarily stopped. It results in incomplete combustion of the coke/fuel inside the furnace and hence leads to rapid reduction of the temperature in the furnace. Therefore this temporary jamming must be prevented by frequent poking of this solidified material by means of a poking bar through the tuyeres. The operator of cupola should always keep himself alert enough for not allowing such solidification for continue melting in furnace for a longer period.

Permanent Jamming of Cupola Furnace

Permanent jamming of cupola furnace means a complete cut-off of the air supply to the cupola due to the permanent choking of the air passage. This occurs on account of the overflow of the slag into the wind chamber. As the metal melts and starts collecting in the well of the furnace, its level rises gradually and the slag being lighter, always floats on the top surface of the molten metal. If, the molten metal is not tapped out in time due to the negligence of the operator, the level of molten metal in furnace will start rising in the well and a stage will come when this level approaches to the tuyere level. Any slightest delay further, in tapping by the cupola operator will cause the slag to flow through the tuyere openings into the wind belt. Since the slag comes in contact with the air at low temperature it quickly solidifies in the wind belt as well as in the tuyers and therefore chock the passages of air flow permanently in the furnace. Hence the cupola furnace reaches in such undesirable condition on account of the above occurrence. Therefore, to avoid such undesired situation, the operator of cupola furnace should always be vigilant enough to tap the molten metal out from well of the cupola furnace before the level of molten metal rises up to the tuyere level. Hence the cupola furnace may continue melting for longer period.

Thermal Efficiency of Cupola Furnace

Thermal efficiency of cupola furnace is the ratio of heat actually utilized in melting and superheating the metal to the heat evolved in it through various means. The total heat evolved involves the heat due burning of coke, heat evolved due to oxidation of iron, Si and Mn and heat supplied by the air blast. During melting it is observed that approximately 48- 70 % of the evolved heat is going as waste.