Main Types of Process Planning

This article throws light upon the three main types of process planning. The types are: 1. Manual Process Planning 2. Automated Process Planning 3. Generative Process Planning.

This type of planning is known as man-variant process planning and is the commonest type of planning used for production today.

Planning the operations to be used to produce a part requires knowledge of two groups of variables:

(i) The part requirements (as indicated by an engineering drawing) and,

(ii) The available machines and processes, and the capabilities of each process.

Given these variables, the planner selects the combination of processes required to produce a finished part. In selecting this combination of processes, a number of criteria are employed. Production cost or time are usually the dominant criteria in process selection; however, machine utilization and routing often affect the plans chosen.

In general, the process planner tries to select the best set of processes and machines to produce a whole family of parts rather than just a single part.

Man-variant process planning (at times) becomes a boring and tedious job. It produces erroneous process plans. This, coupled with the labor intensity of man-variant planning, has led many industries to investigate the automation of process planning.

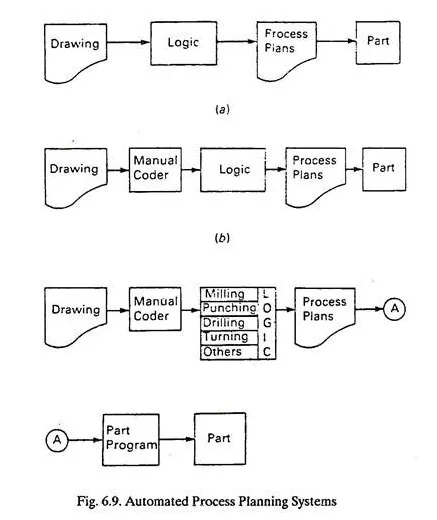

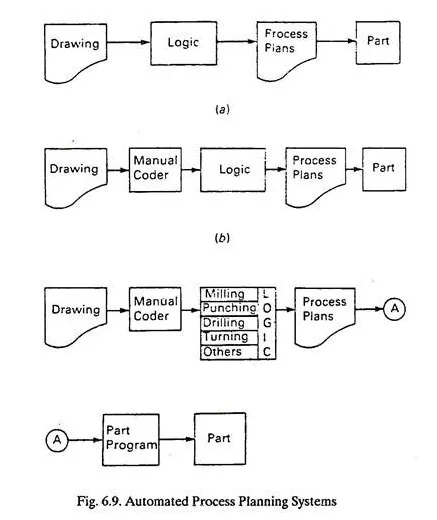

A completely automated process planning system would eliminate all human effort between the preparation of an engineering drawing and a complete process plan for every manufacturing operation. Schematically, the system would correspond to Fig 6.9(a).

The block labeled LOGIC would include the capability to scan and interpret the drawing, to convert this information into process requirements and to select machines, tools and operations to yield an economically acceptable product. Such a system would be truly automated. Self-contained logic would check for contradictory requirements on the engineering drawing.

These requirements would be checked for compatibility with available processes. Selection of the processes (such as turning, milling or stamping) would be based on product requirements, quantities ordered and process capabilities. Whenever contradictory or incompatible requirements were detected, a printed message would indicate the source of the problem and recommend remedial action.

A less automated system is shown in Fig. 6.9 (b). This system needs human assistance to code the engineering drawing data. Thereafter, the system is fully automated. In Fig. 6.9 (c), a still less automated system is shown. For this arrangement, a man must select the process as well as interpret and code the drawing information.

Many developments in computer-aided process planning have focused on eliminating the process planner from the entire planning function. Computer-aided process planning can reduce some of the decision making required during a planning process.

Advantages of computer-aided process planning:

(a) It can reduce the process planning time.

(b) It can reduce the skill required of a planner.

(c) It can create more consistent plans.

(d) It can produce more accurate plans.

(e) It can increase productivity.

(f) It can reduce both process planning and manufacturing costs.

Benefits from computer-aided process planning have been documented by several industries. Such systems can reduce planning time from days to hours or from hours to minutes.

Generative process planning may be defined as a system that synthesizes process information in order to create a process plan for a new component automatically. Process plans are created from information available in a manufacturing database with little or no human intervention.

Upon receiving the design model, the system can generate the required operations sequence for the component. Knowledge of manufacturing must be captured and encoded into efficient software. By applying decision logic, a process planner’s decision-making process can be imitated. Other planning functions, such as machine selection, tool selection, process optimization, and so on, can also be automated using generative planning techniques.

Decisions on process selection, process sequencing, and so on, are all made by the system. However, transforming component data and decision rules into a computer-readable format is still a major obstacle to be overcome before generative planning systems become operational.

Generative method of process planning:

The generative method of process planning essentially consists of four steps:

(1) Describe a part in detail.

(2) Describe a catalog of processes available to produce parts.

(3) Describe the machine tool(s) that can perform these processes.

(4) Create the software to inspect the part, process, and available machinery to determine whether all three are compatible.

Advantages of generative process planning:

(a) It can generate consistent process plans rapidly.

(b) New components can be planned as easily as existing components.

(c) It can potentially be interfaced with an automated manufacturing facility to provide detailed and up-to-date control information.