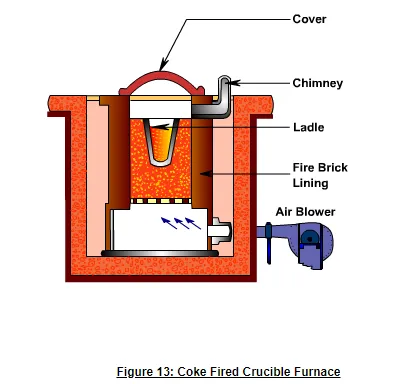

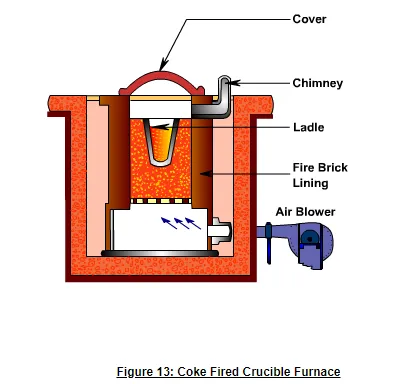

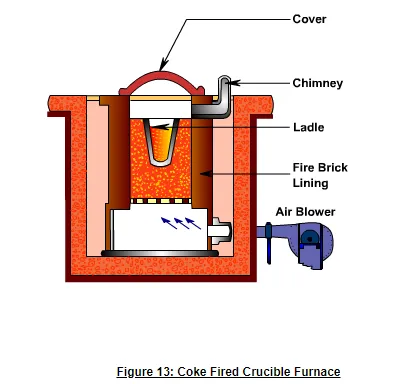

Crucible Furnace

Crucible furnaces are small capacity typically used for small melting applications. Crucible furnace is suitable for the batch type foundries where the metal requirement is intermittent. The metal is placed in a crucible which is made of clay and graphite. The energy is applied indirectly to the metal by heating the crucible by coke, oil or gas.The heating of crucible is done by coke, oil or gas. .

Coke-Fired Furnace

- Primarily used for non-ferrous metals

- Furnace is of a cylindrical shape

- Also known as pit furnace

- Preparation involves: first to make a deep bed of coke in the furnace

- Burn the coke till it attains the state of maximum combustion

- Insert the crucible in the coke bed

- Remove the crucible when the melt reaches to desired temperature

Oil-Fired Furnace.

- Primarily used for non-ferrous metals

- Furnace is of a cylindrical shape

- Advantages include: no wastage of fuel

- Less contamination of the metal

- Absorption of water vapor is least as the metal melts inside the closed metallic furnace