Transfer Molding

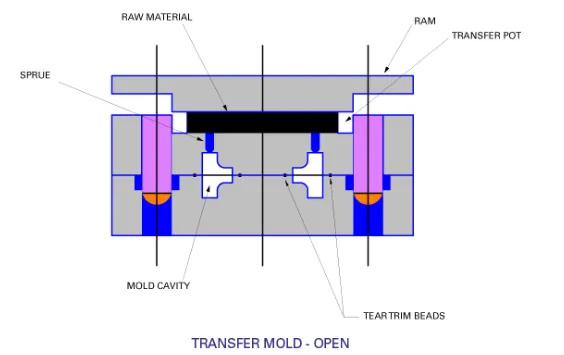

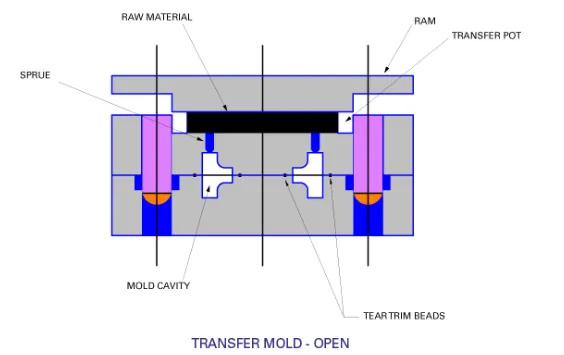

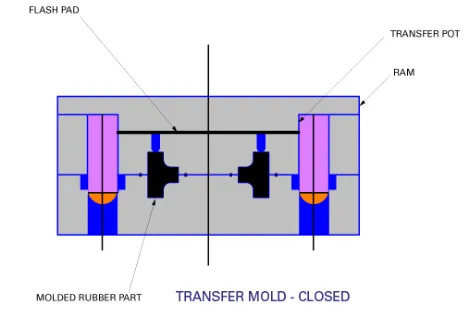

As with compression molding, transfer molding requires secondary raw material preparation into pre-forms. It differs, however, in the placement of these pre-forms into a "pot" located between the top plate and a plunger. When the pre-forms are placed into the pot, the mold is then closed and the material is compressed by the plunger and transferred through sprues into the cavity below.

Some possible advantages of transfer molding over compression molding can include:

The primary disadvantage of transfer molding is found in the increase of waste or excess flash. This can be seen in the "flash pad" or the rubber left in the pot after the transfer is cured which can either be recycled or discarded.