Manufacturing of Bricks for Masonry Construction

The process of manufacturing of bricks from clay involves preparation of clay, molding and then drying and burning of bricks. The bricks are building materials which are generally available as rectangular blocks. The bricks do not require any dressing and brick laying is very simple compared to stone masonry.

For the manufacturing of bricks, the site should be selected based on some important considerations such as:

There are four different operations are involved in the process of manufacturing of bricks:

Preparation of clay for bricks manufacturing is done in six steps: Unsoiling of clay We need pure clay for the preparation of bricks. The top layer of soil may contains impurities, so the clay in top layer of soil about 200mm depth is thrown away. This is called unsoiling. Digging After the removal of top layer, the clay is dug out from the ground and spread on the plain ground. Cleaning In this stage, the clay is cleaned of stones, vegetable matter etc. if large quantity of particulate matter is present, then the clay is washed and screened. The lumps of clay are converted into powder with earth crushing rollers.

Weathering The cleaned clay is exposed to atmosphere for softening. The period of weathering may be 3 to 4 weeks or a full rainy season. Generally, the clay is dug out just before the rainy season for larger projects. Blending If we want to add any ingredient to the clay, it is to be added in this stage by making the clay loose and spread the ingredient over it. Then take small portion of clay into the hands and tuning it up and down in vertical direction. This process is called blending of clay. Tempering In this stage, water is added to clay and pressed or mixed. The pressing will be done by cattle or with feet of men for small scale projects, pug mill is used as grinder for large scale projects. So, the clay obtains the plastic nature and now it is suitable for molding.

In the molding process, prepared clay is mold into brick shape (generally rectangular). This process can be done in two ways according to scale of project.

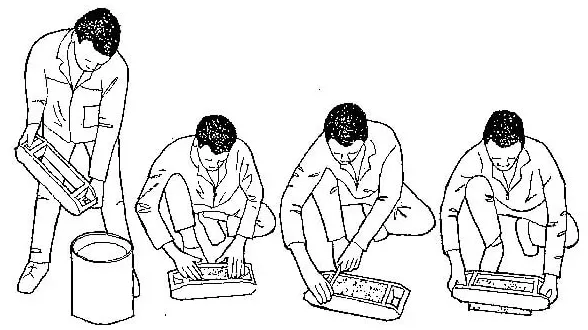

If manufacturing of bricks is on a small scale and manpower is also cheap then we can go for hand molding. The molds are in rectangular shape made of wood or steel which are opened at the top and bottom. The longer sides of molds are projected out of the box to serve it as handles. If we take durability in consideration steel molds are better than wooden molds. In hand molding again there are two types and they are

Ground molded bricks

Table molded bricks

The bricks required are in large quantity, then machine molding is economical and also saves more time. Here also we are having two types of machines,

Plastic clay machines This machines contain an opening in rectangular shape and when we place the tempered clay in to this machine it will come out through this opening. Now, the rectangular strips coming out the opening are cut by wires to get required thickness of brick. So, these are also called wire cut bricks. Now these raw bricks are ready for the drying process. Dry clay machines Dry clay machines are more time saving machines. We can put the blended clay into these machines directly without tempering. Means tempering is also done in this machine by adding some water. When the required stiffness is obtained the clay is placed in mold and pressed hard and well-shaped bricks are delivered. These are called pressed bricks and these do not require drying they may directly sent to burning process.