Plant Layout

Plant layout is a “technique of locating different machines and plant services within the factory so that the greatest possible output of high quality at the lowest possible total cost can be available”.

It signifies the arrangement of machines, work areas, material handling equipment’s, transport, and storing of different materials, products, tools and fixtures etc. Proper plant layout is one of the keys of success in factory management. The layouts for the same product may be numerous, but which costs less in the long run is the best.

Since plant layout is responsible for an orderly flow of materials, productivity and morale of the workers, it is necessary to have systematic layout planning. This has become all the more necessary with the increasing costs of the land, labour and building materials.

Layout should be such that, it can be changed without much difficulty due to expansion, diversification, change in product design or change in technology. In such cases we need to minimise the effects of dislocation i.e., the transition has to be made quickly from old layout to new layout, so as to minimise the production loss.

Most of the handling operations are performed repeatedly throughout the course of production, therefore, if shortest manner of handling is not adopted, this will result wastage of time and shall loose total effectiveness.

Type of building-single storey or multi storey depends upon the availability of land and the type of products to be manufactured and its manufacturing methods. Where manufacturing process involve the gravity flow of products such as chemicals, paints, sugar, refineries, fertilisers etc., multi-storey building must be designed.

A good layout minimises the handling time and efforts, saves the floor space, shortens the travel of materials, increases production and reduces cost by utilising labour more efficiently. If the layout is haphazardous, the products will not be economical and cost may be very high resulting in losses.

Layout for a factory must be decided by considering the following factors:

· Organisation.

· Location of departments.

· Type of product, method of production, production process.

· Production capacity.

· Type of industry, like synthetic, analytic, conditioning or extractive.

· Grouping of machines.

· Material flow pattern.

· Space requirement for machines, work area, material handling, storage, and other facilities.

· Safety factors.

· Health and other factors, like ventilation, natural light, removal of smoke, and fumes etc.

· Provision for future expansion.

· Flexibility for future modifications due to diversification, technology, or product design changes.

· Storage system i.e., centralised or decentralised or a combination of both.

This is a procedure of making the layout of the plant or making improvement in the existing layout with the help of a number of tools and techniques. In this, a plan showing the position of machines, flow of work and material handling devices etc. is prepared to a scale on a drawing sheet or floor.

The various tools and techniques used for the preparation of plant layout are described in short below:

(a) Flow process chart,

(b) Process flow diagram,

(c) Machine data card,

(d) Templates, and

(e) Scale models.

Flow Process Chart:

This is a graphic representation of sequence of operation, transportation, inspection, delays and storage occurring during manufacture. This gives the information regarding distance moved and time required for various activities such as transportation, delay, inspection etc. This chart helps in determining hidden efficiencies in the processes and may suggest rearrangement of layout.

This also points out elimination of unnecessary movement and processes.

Process Flow Diagram:

It is the diagram of building plan representing graphically the movement of materials on the drawing. With its help proper material handling arrangements can be made and it indicates long material hauls and back tracking of present layout, which thereby helps in improving the layout.

Machine Data Cards:

These cards give complete specification of each machine to be installed such as output capacity, foundations, space needed, method of operation, maintenance and handling devices of machines etc.

Templates:

After studying the flow process chart, process flow diagram and machine data cards, a floor plan is prepared by fixing the area occupied by each item to be erected in the shops. This floor plan is prepared at certain scale say 1 cm2 = 1 m2.

Now from thick sheets of paper or card board pieces are cut (known as templates) to represent various items which are to be housed in the plants, and are placed on the floor plans at suitable places. These templates are so arranged as to give best layout. The changes if any, required are made before making the actual layout drawing.

Scale Models:

It is an improvement over the template method. In this tool, instead of templates, use of three dimensional scale models is made. These models may be of wood or metal and when used on a layout, series of additional information about the height and of the projected parts of the machines are obtained. This is similar to a child’s doll house.

This technique is useful for complex layout, requiring initially huge investment.

In conclusion, plant layout is an important consideration. Hence various experts such as production engineer, materials handling engineer, safety engineer and work study engineer etc. should all sit together to arrive for final best shape of layout.

A scientific layout has got the following important advantages:

· It reduces internal transport to a minimum.

· It minimises accidents and makes supervision easy and quick.

· It makes repairs and maintenance easy.

· It yields higher profits. Therefore, higher wages can be paid to workers.

· It reduces labour turn-over.

· It reduces production delays to a large extent.

· It keeps the shops neat and clean.

· It minimises changes in the layout to a large extent every time.

· It keeps control over production.

· It eliminates waste effort and thus speeds of production increases.

· Back tracking is reduced.

· Less capital is spent on machinery.

· It reduces set up and total operation time.

· It reduces wastage and spoiled work.

· Time and motion study can be easily and accurately performed.

· Better utilisation of manpower.

· Improvement in methods of production can be made.

The tool rooms, store rooms, water, power, transportations, cafeteria, wash rooms, lavatories etc. include the service centres of a plant. The shorter the distance from the operations to these centres, the less time will be consumed by workers in using these services.

Generally the service centres are located where the space is available after planning for manufacturing. The exact location is determined by its nature, number of persons to avail such services and how much this service is made use of.

The factors affecting the layout of most important service centres such as store room, transportation, water, and power fire protection are as under:

Store Room:

Store room layout, as far as possible, should satisfy the following essential requirements:

· It should provide an easy receipt, storage, issue and inspection of materials etc.

· It should have enough storage capacities and facilities.

· It should have proper protection against wastage, damage deterioration and thefts.

· It should permit easy and clear identification and location of materials.

· It should be simple and serviceable.

· It should have bins of proper width for handling the materials.

Transportation:

Transportation required in the factory premises is for different purposes, such as transportation of materials and equipment, transportation of labourers and other employees and transportation of products; proper consideration is essential so that the layout is economical and convenient.

Water:

The layout of the water service is very necessary consideration. For this purpose, certain provisions are given in the “FACTORY ACT”, those must be strictly followed. According to Factory Act, in every factory in which more than 250 workers are employed, water coolers should be installed at suitable places.

The water centres should be marked by the word “DRINKING WATER”. Water centres should be located at least 6 m from latrines, urinals and washrooms. There should be one water centre for first 150 workers to 500 workers and one centre for every additional 500 workers.

Power:

The electrical energy required for running the plants may be purchased from an outside source or generated itself.

The electric energy is transformed into mechanical power and is supplied to the machines and equipment’s in the following two ways:

· Group Drive.

· Individual Drive.

Today individual drive is generally adopted. So in the layout, it is to be seen that from where electrical cables will pass and where protecting devices, switches, starters and control panels are to be fixed.

Fire Protection:

For this, suitable places must be allotted in the shop for locating water buckets, sand buckets and fire extinguishers. Inflammable materials must be kept in separate store at a safe distance, minimum 15 m from the general storage.

Provision to escape in case of fire must be kept. A factory employing more than 20 persons and storing, inflammable materials and explosives must arrange for training of persons in the routine to be adopted in case of fire.

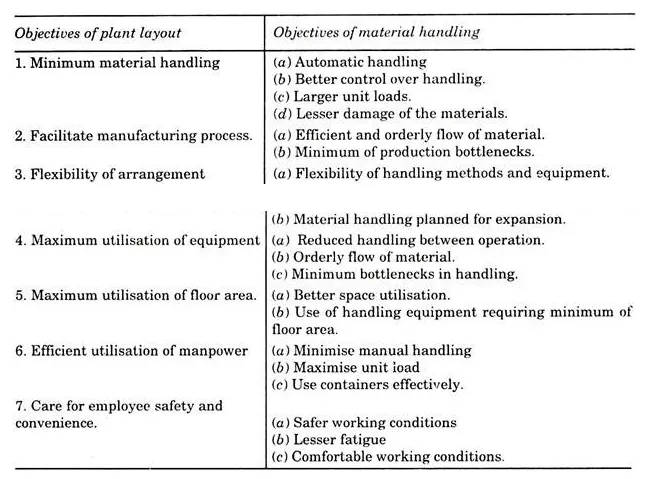

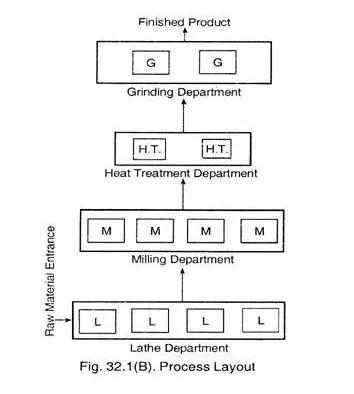

Objectives of plant layout and corresponding objectives of material handling are indicated in the following table:

Inter-Relationship between Plant Layout and Material Handling:

Foregoing discussions emphasize the extreme importance of relationship between them and also with other by both these departments. The success of a factory largely depends on the relationship of these departments.

Some of such fields are mentioned hereunder:

1. Production:

For production function, utmost cooperation is required between plant layout engineers, material handling engineers, and production engineers.

2. Plant Engineering:

For maintenance etc., cooperation between these two departments is necessary.

3. Quality Control:

In order to avoid damages in the path during handling, cooperation between them is essential.

4. Safety:

Since large number of accidents occur during handling, both these departments must work closely with the safety engineer to design the layout and handling methods, equipment etc.

5. Sales and Distribution:

For packaging, loading system cooperation of these two departments with marketing and sales department is essential.

It is not necessary that layout engineer deals with only new layout i.e., layout problems of new facilities. Such problems are faced only once; however he is mostly involved in problems related to the re-layout of an existing process or an alteration in the existing arrangement.

Some of the examples of re-layout problems are:

· Change in the design of part. This calls for the change in the process and may require some alterations in the existing layout.

· Layout change due to the change in method of production.

· Expansion in production capacity.

· Reduction in production capacity.

· Diversification i.e., addition of a new product.

· Planning a new facility or a new department.

· Shifting a department.

· Replacing equipment with advanced technology.

Symptoms of Bad Layout:

· Some machines heavily loaded and some remain idle for long periods.

· Excessive handling by skilled workers.

· Long production cycles.

· Stock control difficulties.

· Bottlenecks in production.

· Poor utilisation of available space.

· Delays in delivery.

· Excessive fatigue on workers.

· Backtracking.

· Excessive temporary storage.

· Poor house-keeping.

· Difficulty in supervision and control.

· Idle workers and equipment.

· Obstacles in material flow.

Good layout can easily be observed by following characteristics:

· Minimum handling between operations.

· Minimum handling distances.

· Straight passages.

· Minimum backtracking.

· Minimum goods in process.

· Planned material flow pattern.

· Layout adoptable to changing conditions.

· Proper location of services.

· Maximum automatic handling.

· Control over noise, dirt, fumes, dust, humidity, temperature etc.

· Minimum walking by operation people.

· Minimum handling by skilled workers.

· Scrap removal be properly planned.

· Minimum re-handling.

Following are the basic principles of “best layout” which should be taken into consideration by plant layout engineer and material handling engineer while designing a plant layout:

1. Principle of over-all integration:

According to this principle, the best layout is one which integrates the man, materials, machinery, supporting activities and any other such factors that result in the best compromise.

2. Principle of minimum distance:

According to this principle, other things being equal, the best layout is one in which men and materials have to move the minimum distance between operations.

3. Principle of Flow:

Muther said that, other things being equal, the best layout is one which arranges the work area for each operation or process in the same order or sequence that forms, treats or assembles the materials.

4. Principle of Cubic Space:

According to this, the best layout is one in which all the available space both vertical and horizontal is most economically and effectively used.

5. Principle of Satisfaction and Safety:

According to this other things being equal, the best layout is one which makes work satisfying, pleasant and safer for workers.

6. Principle of Flexibility:

It means the best layout is one which can be adopted and re-arranged at a minimum cost with least inconvenience.

These are:

Type of Industry:

Industries are generally classified according to their processes of manufacture.

The process of manufacture can be classified into four categories:

(a) Synthetic Process:

When two or more materials are mixed to get a product, the process is known as synthetic process. The example of such a process is to produce the cement by mixing limestone and clay.

(b) Analytic Process:

This is opposite of synthetic process. It is the breaking up of a material into several parts. The refining of petroleum is the example of this case.

(c) Conditioning Process:

In the conditioning process, the form of raw material is changed into desired product as in jute industry.

(d) Extractive Process:

In this type, by applying heat, desired product is extracted from the original raw material e.g. manufacture of Aluminium from Bauxite.

Type of Products:

Type of product means whether the product is heavy or light, large or small, liquid or solid. It is also a consideration in plant layout.

Volume of Production:

According to this point, while plant layout is being done, it should be kept in mind that, what volume is required to be produced. In this case, it should be seen that whether (a) Job Production, (b) Batch Production or (c) Mass Production is being adopted.

Influence of Processes:

Last, but not the least factor to consider, is the process through which the material passes in the concern. Much care should be given to the material handling problem, position of store room and tool room.

Keeping in view the type of industry and volume of production, there can be following methods of layout:

(a) Line or Product Layout.

(b) Functional or Process Layout.

(c) Fixed Position Layout.

(d) Combination.

Line or Product Layout:

This type of layout is very popular in mass production. In this layout only one product or one type of product is produced in an operating area. In order to justify the line layout, the product must be standardised and manufactured in huge quantities. The machines in such layout are arranged in the order in which they are to be used.

The operations are performed in a sequence. All parts, sub-assemblies etc. are started at right time so as to be ready at the required time and kept moving until the finished product is available at the end of the assembly line. This arrangement is also known as the “synthetic system” of manufacture.

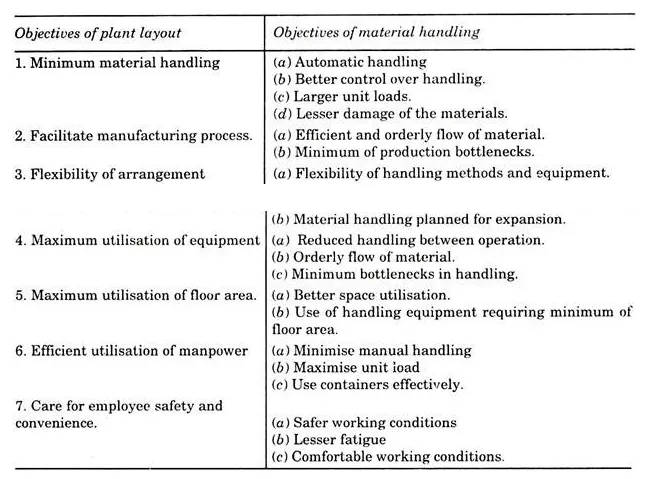

For example, suppose a factory manufactures taps, drills, reamers and cutters. Production of each of these articles may be made in a separate department and in each department machines will be laid out in that sequence in which the operations have to be performed on the product.

For example, in the reamer department, there will be group of lathes to turn the reamer blanks, the lathes will be followed by the milling machines which square the shank and mill the flutes; next to the milling machines will be furnaces for heat treating the reamers and last will come the grinding machines to do the finishing. Fig. 32.1 (A) shows an arrangement of this type.

Suitability:

This is suitable for continuous process industries such as automobile manufacturing or chemical industries.

Advantages:

· It lowers the overall manufacturing time as product proceeds rapidly from operation to operation without any handling.

· Less space is needed for placing machines.

· There is minimum of handling and transportation.

· There is less work-in-process.

· Better utilisation of machines and labour.

· It minimises counting, inspecting, clerical work etc.

· There is smooth flow of materials.

· Promises for supply of products to customers are more reliable.

· Use of gravity and power conveyors for material handling reduces the necessity of aisles.

· Production control is simplified greatly.

Disadvantages:

· When the model or type changes, the layout of machinery also requires a change.

· All machines in the arrangement cannot be used to their maximum capacities.

· The manufacturing cost rises with a fall in the volume of production.

· If one or more lines are running light, there is great machine idleness.

· Specialised and strict supervision is needed.

· If any of the machines in the line breaks down the other machines have to remain idle till that machine becomes again ready to commence operation.

· For expansion purpose, it is not possible to add more machines.

· Each worker performs job on a particular machine, so he is not skilled for other machines or operations.

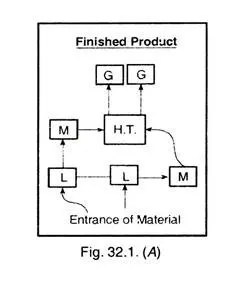

Functional or Process Layout (Group Technology):

Under this arrangement each department or section is responsible for carrying out a particular process and not a particular product as under line type layout. There are similar operations in each department or section.

In a job order production factory, there are no standard products or if any, they repeat orders. Therefore, machines in this type of layout are generally arranged on functional basis. This type is also called analytical layout.

Thus for example, in a factory manufacturing taps, drills, reamers and cutters mentioned above there may be four departments, the lathe, milling, the heat treatment and the grinding, each responsible for a specific operation. All the products manufactured in this factory have to pass through these four principle operations. Fig. 32.1(5) shows this arrangement.

Suitability:

In this, similar equipment and similar machines are grouped together. This is very useful where low volume of production is required.

Advantages:

· Similar jobs are manufactured on similar machines, hence supervision is simple.

· Less machines are required.

· This offers great incentive for each worker to raise the level of performance.

· There will be better control on precision or complicated process.

· The layout is flexible, hence it can easily be managed to change in the rate of production, in the design of products, in the methods of production or in the raw materials used.

· Breakdown of any one machine does not affect production as its work can be done on a standby machine.

· Capital layout for machines is minimum.

· New workers have better training facilities on the job. Workers know how to run various machines in the group and also to set-up work.

· Foremen become specialised in the performance of the job and know all about the equipment’s and their operations.

Disadvantages:

· Handling and back-tracking of materials is too much.

· It makes necessary to plan and supervise the work of each department, each worker and machine. This makes production control more difficult and more costly.

· Generally more floor area is required.

· Specialization creates monotony and there will be difficulty for the workers to find job in other industries.

· Total production cycle time is more due to long distances and waiting.

· Routing and scheduling is more difficult, as the work does not flow through any definite mechanical channels.

· There are no cheaper and automatic devices for internal transportation.

· Inspection of work for each operation is necessary as the material passes to the next department. This results in more inspections and causes delay.

· More training will be required to prepare the workers for the jobs.

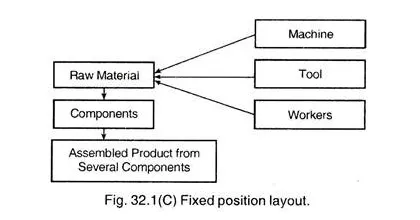

Fixed Position Layout:

This type of layout is used in manufacturing huge air crafts, ship vessels, and pressure vessels etc. where the products are too heavy. For such type of products, it is convenient and economical to bring the tools, machines, men etc. to the work place.

This type of layout was very common before the Industrial Revolution but the present industries have grown much in size and complexity, therefore, now-a-days it is easy and more economical to move the materials to the equipment and machines. Fig. 32.1 (C) shows a simple arrangement of this type of layout. This type is also known as “Static Product Layout”.

Advantages:

· Capital investment is minimum.

· Continuity of operations is ensured.

· Less total production cost.

· Less material movement.

Disadvantages:

· Machines and tools etc. take more time to reach to the work place.

· Highly skilled workers are required.

· Complicated jigs and fixtures may be required in fixing jobs, tools etc.

Combination Layout:

Now-a-days any one form of layout in pure state is rarely found. Therefore, a combination of any of the three methods is formed according to the requirement of an industry. In factories, where products are first manufactured and then assembled this method is mostly used.

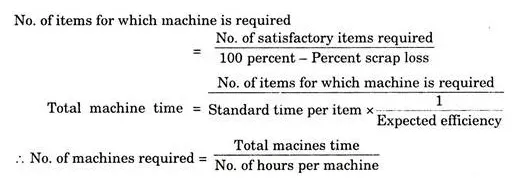

In order to lay-out a plant, the number of machines required should be known.

This can be calculated in the following way:

As far as possible certain amount of flexibility of arrangement in operation is essentially desired in a plant layout. Economy should be the prime consideration in layout.

When changes are affected in the product design, methods of operations, the type of the product or the production quantities then the machines or departments may also have to be rearranged. Therefore, it is necessary to design layouts in such a way so as to minimise the effect of subsequent alterations on the production process.

Flexibility in layout can be secured in several ways:

· Keep enough unobstructed floor areas.

· Separate electric motors to be allowed on individual machines.

· Mobile machinery should be used.

· Equipment can be placed on rubber footings instead of being mounted permanently.

· As far as possible small tools should be used.

· Portable conveyor units may be employed.

· Overhead electrical lighting arrangements easily detachable can be used instead of permanent fittings.

· Make use of portable jigs and fixtures.