Optical Rotary Encoder Options

An optical rotary encoder uses a reliable, defined pattern of light-and-dark to determine the position of the shaft and, therefore, the position of an object.

The most basic design for an optical rotary encoder is a mask encoder, but there are a multitude of other options that provide even more stability and more feedback information in an increasing variety of application environments.

Optical Rotary Encoder Basics

In a sense, the optical rotary encoder output is binary; it is either light or dark.

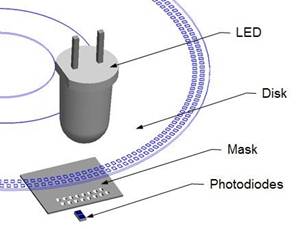

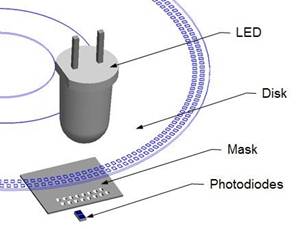

An optical rotary encoder has a moving disk, with concentric tracks etched into the disk. Periodically, these tracks have an opening, called a window. The windows of every track are offset, so that each revolution of the optical rotary encoder has a different light/dark pattern.

On the other side of the optical rotary encoder is the mask, which is usually connected directly to a sensor, to increase the resolution. The mask, like the disk, is also grooved with corresponding tracks and windows. As the light source shines through the moving disk onto the mask of the optical rotary encoder, the different, unique light patterns illuminate the sensor.

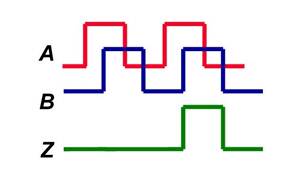

Each optical rotary encoder track contains one or two sensors. Each sensor outputs its individual signal, and the sensors outputs are slightly offset from each other, creating slightly offset outputs. The two offset signals interact differently with the light source, creating a unique optical rotary encoder pattern. The pattern is the quadrature.

Since each arc revolution has a completely different pattern, an optical rotary encoder can be exceptionally accurate.

The most basic optical rotary encoder design has certain limits in signal stability and count methodology because it is limited to only a couple of signal outputs. The basic A/B signal is not the limit of optical rotary encoder design. Innovation for both incremental and absolute encoders allows optical engines to be highly accurate and to perform better in more extreme environments:

An optical rotary encoder engine can bring almost unparalleled accuracy for both incremental and absolute encoders. Look at the demands of your application – whether it is the delicate movement of a medical device or the precision of robotic assembly line units – to determine whether an optical rotary encoder can offer the required performance in the application environment: