How to Measure Flow Using Orifice Meter

Basic Principle of Orifice Meter

When an orifice plate is placed in a pipe carrying the fluid whose rate of flow is to be measured, the orifice plate causes a pressure drop which varies with the flow rate. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure drop becomes a measure flow rate. The flow rate is given by.

![]()

Where, Qa = flow rate

Cd = Discharge coefficient

A1 = Cross sectional area of pipe

A2 = Cross sectional area of orifice

P1, P2 = Static Pressures

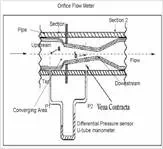

Description of Orifice Meter

The main parts of an orifice flow meter are as follows:

● A stainless steel orifice plate which is held between flanges of a pipe carrying the fluid whose flow rate is being measured.

● It should be noted that for a certain distance before and after the orifice plate fitted between the flanges, the pipe carrying the fliud should be straight in order to maintain laminar flow conditions.

● Openings are provided at two places 1 and 2 for attaching a differential pressure sensor (U-tube manometer, differential pressure gauge etc) as shown in the diagram.

Operation of Orifice Meter

● The detail of the fluid movement inside the pipe and orifice plate has to be understood.

● The fluid having uniform cross section of flow converges into the orifice plate’s opening in its upstream. When the fluid comes out of the orifice plate’s opening, its cross section is minimum and uniform for a particular distance and then the cross section of the fluid starts diverging in the down stream.

● At the upstream of the orifice, before the converging of the fluid takes place, the pressure of he fluid (P1) is maximum. As the fluid starts converging, to enter the orifice opening its pressure drops. When the fluid comes out of the orifice opening, its pressure is minimum (p2) and this minimum pressure remains constant in the minimum cross section area of fluid flow at the downstream.

● This minimum cross sectional area of the fluid obtained at downstream from the orifice edge is called VENA-CONTRACTA.

● The differential pressure sensor attached between points 1 and 2 records the pressure difference (P1 – P2) between these two points which becomes an indication of the flow rate of the fluid through the pipe when calibrated.

Applications of Orifice Meter

1. The concentric orifice plate is used to measure flow rates of pure fluids and has a wide applicability as it has been standardized.

2. The eccentric and segmental orifice plates are used to measure flow rates of fluids containing suspended materials such as solids, oil mixed with water and wet steam.

Advantages of Orifice Meter

1. It is very cheap and easy method to measure flow rate.

2. It has predictable characteristics and occupies less space.

3. Can be use to measure flow rates in large pipes.

Limitations of Orifice Meter

1. The vena-contracta length depends on the roughness of the inner wall of the pipe and sharpness of the orifice plate. In certain cases it becomes difficult to tap the minimum pressure (P2) due to the above factor.

2. Pressure recovery at downstream is poor, that is, overall loss varies from 40% to 90% of the differential pressure.

3. In the upstream straightening vanes are a must to obtain laminar flow conditions.

4. Gets clogged when the suspended fluids flow.

5. The orifice plate gets corroded and due to this after sometime, inaccuracy occurs. Moreover the orifice plate has low physical strength.

6. The coefficient of discharge is low.

Note: the materials used for maintaining orifice plate are stainless steel, phosper bronze, nickel and monel.