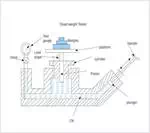

Dead Weight Tester

Description

The dead weight tester apparatus consists of a chamber which is filled with oil free impurities and a piston – cylinder combination is fitted above the chamber as shown in diagram. The top portion of the piston is attached with a platform to carry weights. A plunger with a handle has been provided to vary the pressure of oil in the chamber. The pressure gauge to be tested is fitted at an appropriate plate.

Operation

the dead weight tester is basically a pressure producing and pressure measuring device. It is used to calibrate pressure gauges. The following procedure is adopted for calibrating pressure gauges. Calibration of pressure gauge means introducing an accurately known sample of pressure to the gauge under test and then observing the response of the gauge. In order to create this accurately known pressure, the following steps are followed.

The valve of the apparatus is closed.

A known weight is placed on the platform.

Now by operating the plunger, fluid pressure is applied to the other side of the piston until enough force is developed to lift the piston-weight combination. When this happens, the piston weight combination floats freely within the cylinder between limit stops.

In this condition of equilibrium, the pressure force of fluid is balanced against the gravitational force of the weights puls the friction drag.

Therefore, PA = Mg + F

Hence : P = Mg + F / A

where, P = pressure

M = Mass; Kg

g = Acceleration due to gravity ; m/s²

F = Friction drag; N

A = Equivalent area of piston – cylinder combination; m²

Thus the pressure P which is caused due to the weights placed on the platform is calculated.

After calculating P , the plunger is released.

Now the pressure gauge to be calibrated is fitted at an appropriate place on the dead weight tester. The same known weight which was used to calculate P is placed on the platform. Due to the weight, the piston moves downwards and exerts a pressure P on the fluid. Now the valve in the apparatus is opened so that the fluid pressure P is transmitted to the gauge, which makes the gauge indicate a pressure value. This pressure value shown by the gauge should be equal to the known input pressure P. If the gauge indicates some other value other than p the gauge is adjusted so that it reads a value equal to p. Thus the gauge is calibrated.

Applications:

It is used to calibrated all kinds of pressure gauges such as industrial pressure gauges, engine indicators and piezoelectric transducers.

Advantages:

it is simple in construction and easy to use.

It can be used to calibrated a wide range of pressure measuring devices.

Fluid pressure can be easily varied by adding weights or by changing the piston cylinder combination.

Limitations:

the accuracy of the dead weight tester is affected due to the friction between the piston and cylinder, and due to the uncertainty of the value of gravitational constant 'g'.