Elastic diaphragm gauges

Basic principle of Elastic diaphragm gauges:

when an elastic transducer (diaphragm is this case) is subjected to a pressure, it deflects. This deflection is proportional to the applied pressure when calibrated.

Description of Elastic diaphragm gauges:

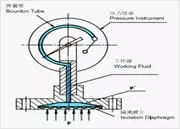

The main parts of the diaphragm which is a thin circular plate (made of springy metal) is fixed firmly around its edges. The diaphragm may either be flat or corrugated.

A corrugated diaphragm has been shown in the diagram where the displacement of the diaphragm is magnified by mechanical means. A flat diaphragm has been shown in the diagram where the displacement of the diaphragm is sensed by a secondary transducer such as a parallel plate capacitor.

The top portion of the diaphragm is fixed with a boss of negligible weight. This boss is in-turn connected to a link – sector – pinion arrangement in case of a diaphragm gauge using mechanical means for displacement magnification. A pointer is connected to the pinion which makes it sweep over a pressure calibrated scale. If the displacement is sensed by a secondary transducer such as a parallel plate capacitor, its movable plate is connected to the boss.

Operation of Elastic diaphragm gauges:

The bottom side of the diaphragm is exposed to the pressure which is to be measured. Due to the applied pressure, the diaphragm deforms. That is the diaphragm tends to move upwards. This deformation of the diaphragm is proportional to the applied pressure. In a mechanical system, this deformation is magnified by the link – sector – pinion arrangement. That is, the linear displacement of the diaphragm is converted to a magnified rotary motion of the pinion. When the pinion rotates, it makes the pointer attached to it to assume a new position on the pressure calibrated scale which becomes a measure of the applied pressure. In case of the arrangement with the parallel plate capacitor, the movable plate moves upwards, thus reducing the gap between the plates. This makes the capacitance of the capacitor becomes a measure of the applied pressure. As the top side of the diaphragm is usually subjected to the atmospheric pressure, (generally less than the applied pressure) elastic diaphragm gauges usually read gauge pressure.

Applications of Elastic diaphragm gauges:

They are used to measure medium pressure.

But they can also be used to measure low pressures including vacuum.

They are used to measure draft in chimneys of boilers.

Advantages of Elastic diaphragm gauges:

Best advantage is they cost less

They have a linear scale for a wide range

They can withstand overpressure and hence they are safe to be used.

No permanent zero shift.

They can measure both absolute and gauge pressure, that is, differential pressure.

Limitations of Elastic diaphragm gauges:

Shocks and vibrations affects their performance and hence they are to be protected.

When used for high pressure measurement, the diaphragm gets damaged.

These gauges are difficult to be repaired.

Note: diaphragm materials:

Metals : stainless steel, inconel, monel, nickel and beryllium copper.

Non – Metals : Nylon, teflon and buna N rubber.