What is Rotameter or Variable-Area Meter?

Rotameter or Variable Area meter is an instrument used to measure the flow rate of a fluid by using a simple float (let us say a small triangle shaped block) to float in the moving fluid. The operation of the Rotameter is explained in detail below.

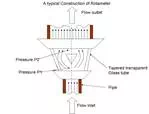

Parts of the Rotameter:

The main parts of a Rotameter are as follows:

A tapered transparent glass tube graduated to read flow rate directly.

A float is used whose density is greater than the flowing fluid. The float’s diameter is such that it completely blocks the inlet of the tapered transparent glass tube.

Operation of Rotameter:

As the fluid whose flow rate is being measured comes and touches the bottom portion of the float blocking the inlet of the tapered transparent glass tube, the float starts to rise when the following happens:

Pressure of flowing fluid + flowing buoyancy is greater than downward pressure due to weight of the float.

When the float rises, an annular space is created between the periphery of the float and the inner wall of the tapered transparent glass tube. This annular space which is concentric opening through which the fluid passes to the other side of the instrument keeps on increasing until the following happens:

(pressure of the flowing fluid) + (fluid buoyancy) = (Downward pressure due to weight of the float)

When this happens, the float stops rising further and stops at a particular position, that is, the float comes to equilibrium.

Thus, increase in flow rate will make the float to rise higher and vice versa. That is, the position of the float becomes a direct indication of flow rate. Hence the tapered transparent glass tube can be graduated suitably by proper calibration to get a direct indication of flow rate by noting the position of the float with respect to the graduations on the tapered tube.

The instrument has to be designed in such a manner so that the effects of changing viscosity and density are minimized leaving only pressure of the flowing fluid as a variable.

Application of the Rotameter:

1. Rotameter can be used to measure flow rates of corrosive fluids.

2. It is particularly useful to measure low flow rates

Advantages of Rotameter:

1. Flow conditions are visible.

2. Flow rate is a linear function (uniform flow scale).

3. Can be used to measure flow rates of liquids, gases and vapours.

4. By changing the float, tapered tube or both, the capacity of the Rotameter can be changed.

Limitations of Rotameter:

They should be installed vertically.

They cannot be used in measurements of moving objects.

The float will not be visible, when colored fluids are used, that is, when opaque fluids are used.

For high pressure and temperature fluid flow measurements, they are expensive.

They cannot be used for fluids containing high percentage of solids in suspension.