Different types of level gauges

Slight glass level gauge:

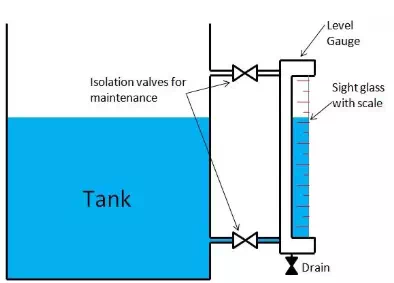

A glass of sight or a water gage is a transparent tube through which a tank or boiler operator can observe the level of liquid contained in it.

It is positioned parallel to the vessel along the elevation over which the level is to be indicated and mounted with appropriate fittings for retaining the pressure and sealing the ends of the sight tube.

However, this building is not well adapted for use with hazardous process liquids.

Reflex Gauges:

A reflex gage is more complicated than a slight glass, but it can make a better difference between air (steam) and fluid (water).

The gage comprises a vertically oriented slotted steel frame with a powerful glass tray installed on the open end of the cabinet facing the user, rather than holding the documents in a glass box.

Most of the light is transferred from the bottom of one drawer to the next and back to the user in the area that is contact with the water, appearing creamy white. In the area in touch with the fluid, most of the light is refracted into the fluid, which causes this area to look nearly black to the user.

Bi-Color Gauges:

For caustic media, a bi-colour gage is usually chosen to provide protection for the crystal. The gage comprises of a vertically oriented, slotted steel frame with a powerful simple front and back glass.

The front and rear surfaces of the body are in vertical planes that are not parallel. Behind the reference body are light sources, typically red and green, with two quite distinct colors. The fluid area looks blue to the viewer due to the distinct refraction of blue and blue light, while the gas area looks purple

Magnetic Gauges:

The magnetic value gage does not take an immediate view of the point (i.e., glass is not needed), the test room can be transparent and the building of welded steel is usually used.

This significantly improves the variety of working temperatures and reduces the roughness relative to test glass rooms. The broad temperature spectrum is feasible because the chamber of measurement can have about the same heat growth ratio as the ship, and there is no plastic to interact with the chamber of steel.