What is Reliability Centered Maintenance (RCM)?

Reliability Centered Maintenance (RCM) is a process used to determine what must be done to ensure that a physical asset can continue to fulfil the expected function in the context of its current operation.

RCM is the maintenance approach that combines the practices and strategies of preventive maintenance (pm) and corrective maintenance (cm) to maximize the lifetime and function of assets/systems/ equipment with minimal costs (minimum cost)

Scope of RCM:

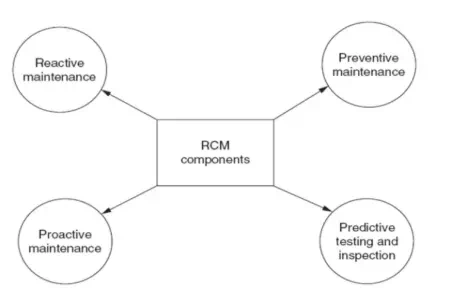

There are four major components in reliability centered maintenance (RCM) described in the figure below, namely reactive maintenance, preventive maintenance, predictive testing and inspection, and proactive maintenance.

Preventive maintenance (PM):

Preventive maintenance can be interpreted as a maintenance action to maintain the system/sub-assembly in order to continue to operate according to its function by preparing a systematic inspection, detection and correction of small damage to prevent the occurrence of greater damage.

Reactive Maintenance :

Reactive Maintenance This type of treatment is also known as a breakdown, justifying if there is damage, run-to-failure or repair maintenance.

When reactive maintenance is rarely applied, the turnover rate is high, maintenance work is rarely done, the high percentage of unplanned maintenance activities is common.

Predictive Testing:

PTI can be used to create a schedule from time-based maintenance because the results are guaranteed by the condition of the monitored equipment. PTI data taken periodically can be used to determine equipment condition trends, data comparisons between equipment, statistical analysis processes, etc.

Proactive Maintenance:

Proactive Maintenance This type of treatment helps improve care through actions such as better design, workmanship, installation, scheduling and maintenance procedures.

The characteristics of proactive maintenance include implementing an ongoing development process, using feedback and communication to ensure that the design/procedure changes made by the designer/management are effective, ensuring that no maintenance effects occur in the overall isolation