Basics of Electro-hydraulic actuator

Electro-hydrostatic actuator (EHA) replace hydraulic systems with electrical power-only self-contained actuators. EHAs eliminates the need for separate hydraulic pumps and tubing.

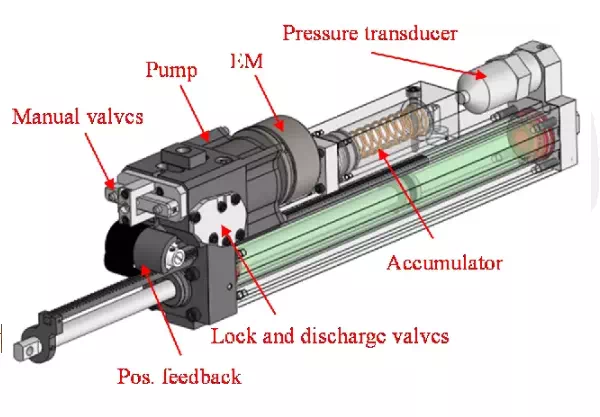

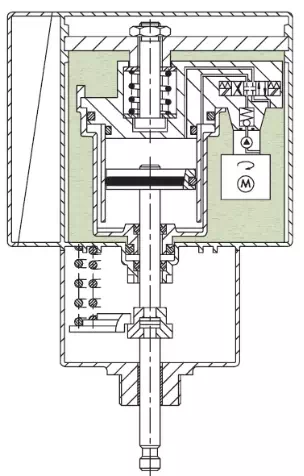

In most cases, hydraulic electrical actuators include a closed hydraulic system consisting of an electrical drive motor, a pump and a hydraulic cylinder with plunger and actuator stem.

Position control is often integrated, i.e. a force balance element with a generally 4 to 20 mA electrical input signal and corresponding feedback via a range spring.

How does an electro-hydraulic actuator work?

A flapper-nozzle system controls the pressures within the double-acting hydraulic cylinder through a special hydraulic high-pressure valve until the desired position of the valve stem is reached.

This results in a proportional relationship between the input signal and valve travel (control valve stroke). Like an electro-mechanical actuator, it is possible to reverse the direction of movement and force.

If a plant has numerous electro-hydraulic actuators, a central hydraulic unit is often used.

Advantages of electro-hydraulic actuators:

· Very high actuator thrusts attainable.

· Relatively high control rate (stroking speed) possible.

· High rigidity (travel stiffness) dampens oscillations of valve stem.

· Automatic failure position in case of auxiliary energy loss.

Disadvantages of electro-hydraulic actuators:

· Very heavy, extensive construction, expensive.

· In most cases, not every mounting position suitable.

· Protection against explosion attainable only with high cost.

· Unsuitable for extremely high and low temperatures.

· Sensitive to rough service conditions, frequent maintenance required