Displacer level switches working, Displacer V/S Float

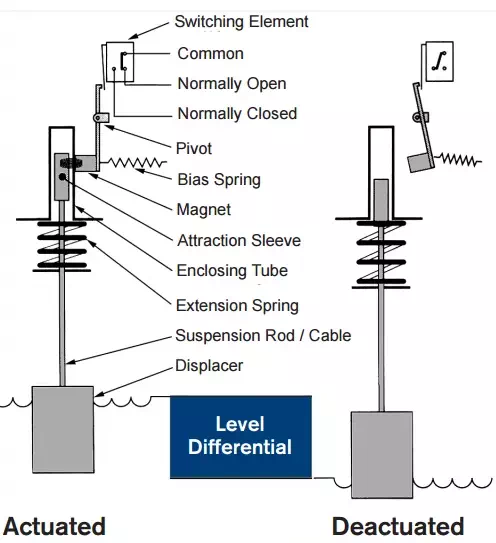

Displacer controls provide float-operated control with additional characteristics. The detector is a spring-suspended weight (the displacer), stronger than the fluid.

A buoyancy force is generated when fluid touches the displacer, which causes the displacerís efficient weight to alter. This allows the spring to mildly retract to a fresh place of balance.

The attachment collar also shifts up into the internal magnetic field when the spring retracts, thus overcoming the negative spring force and actuating the changing component.

Difference between Float & Displacer:

∑ Float switches are accessible in a glandless layout and are capable of failing secure operation under severe process circumstances, unlike displays that can provide a route of leakage if the load pipe falls.

∑ A float usually travels above the fluid ground while a displacer stays either partially or completely submerged in the fluid method.

∑ In the event of turbulent, surging, frothy and foamy facilities, displacer switches are regarded as extra robust and reliable relative to conventional float stage switches.

∑ Displayer settings can be altered very readily as they can be moved anywhere along the suspension cord path. In addition, these tier systems provide tank-to-tank interchangeability.

∑ It is much easier to test the proper functioning of a displacer switch than a usual float level switch, since the former requires only the lifting of a suspension, whereas the latter requires the filling of liquid in the tank up to the actuation mark.