What is superheater?

The superheater is one component in the boiler that serves to further heat the steam to produce steam that meets the requirements for turning turbines.

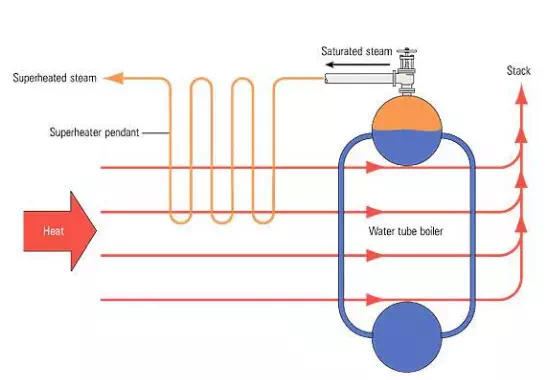

The superheater is a collection of boiler pipes located in the flow of hot gas from combustion. The heat from this gas is transferred to Saturated Steam in the superheater pipe, so it turns into superheated steam

Working & Components of superheater:

This superheater has two parts, the primary superheater and the secondary heater. The primary superheater is the first heater that is passed by steam after the steam comes out of the steam drum.

After the steam is heated on the super primary heater, eating steam will be passed on the secondary superheater to be heated again. So on the secondary superheater steam formed is the hottest steam among the others.

Steam from the secondary superheater which becomes superheated steam. SH steam will flow to rotate High-Pressure Turbine and then the pressure and temperature will drop.

The superheater component consists of:

Combustion chamber :

Is the space used for the fuel combustion process to heat steam.

Burner:

Is a tool used to burn fuel in the combustion chamber. So, the temperature of the combustion chamber increases. The heat from the combustion burner is used to heat the steam that is flowed into the combustion chamber.

Steam coil

Is a steam pipe in the form of a circular squirrel

Measurement instrument

Is a tool to find out process parameters such as temperature and pressure of combustion, the temperature of steam in and out whether it is desired or not.

Since steam can only be superheated when there is no water left around to evaporate, any superheated steam boiler takes steam at the boiler outlet to superheat.

The steam flows through a connecting pipe to a header where itís distributed through a number of parallel tubes exposed to the furnace (radiant superheater) or flue gases after they pass through the screen tubes.