What is Pull Cord Switch?, Itís Working

Pull Cord Switch is an emergency switch to stop the conveyor instantly in any dangerous condition or when an accident occurs.

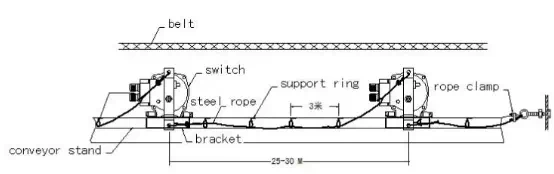

Since the traction cable switch is designed in such a way that it must be installed on the side of the conveyor belt and the traction cable must be mounted along the conveyor, the switch can be operated in any position.

The pull cord switch is a switch that is mounted along a conveyor beam and is manually operated by a cable extending along the conveyor. The cable can be pulled at any point on the conveyor as an emergency stop.

Installation:

The traction cable switch is installed on the side of the conveyor belt and the traction cable is mounted along the conveyor belt. When an accident occurs on the conveyor belt, the worker can stop the conveyor belt in any position by pulling the rope to drive the turning of the drive arm.

The rotation can put the torsion spring in motion through the transmission shaft to drive the cam in the displacement. Then you can activate the microswitches to cut the control wiring. Thus the belt conveyor can stop the operation.

Construction:

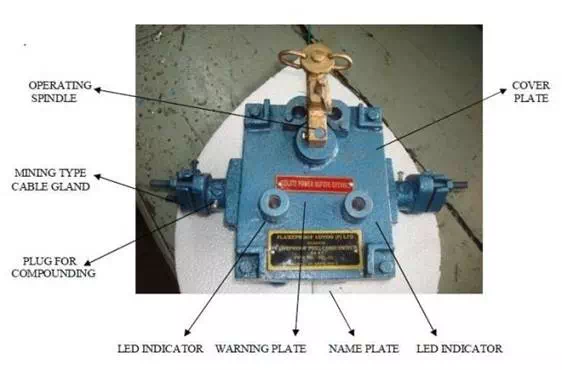

The pull cord switch is housed in a dustproof and dustproof housing with IP65 degree of protection. The rugged and rugged cam switch with rugged contacts is used to extend the service life.

Operation handle equipped with spring steel rings on both ends to fix the rope. The design of the rings provides maximum flexibility in operating conditions. The housing is painted with epoxy to give a high resistance to corrosion. The switch is designed with a manual reset mechanism.

Operation:

The pull cord switch is mounted on the side of the conveyor of the conveyor belt, preferably approximately every 20-25 meters. When the rope is pulled on either side. The switch is operated. Unless and until the handle is manually reset to the normal position, the switch remains in operating condition.

All pull cord switches installed along a single belt are electrically wired in series and connected to the control station by a two-wire cable. Therefore, the activation of any of these pull wire switches will stop the conveyor in question until the particular switch is manually reset.